When deciding between a metal vs wood building, one of the most important and often misunderstood questions is this: Which one actually lasts longer? At first glance, it might seem like a simple comparison. Steel is stronger, so it must last longer, right? On the other hand, we’ve all seen 100-year-old wooden barns still standing tall. So what’s the real answer?

The truth is that longevity isn’t just about materials. A building’s lifespan depends on how it’s built, where it’s built, how it’s used, and most critically how it’s maintained. In this blog, we’ll break down the realistic life expectancy of both metal and wood buildings, what typically causes each type to fail, and how much maintenance each really needs over time.

Metal vs Wood Buildings Lifespan: The Quick Comparison

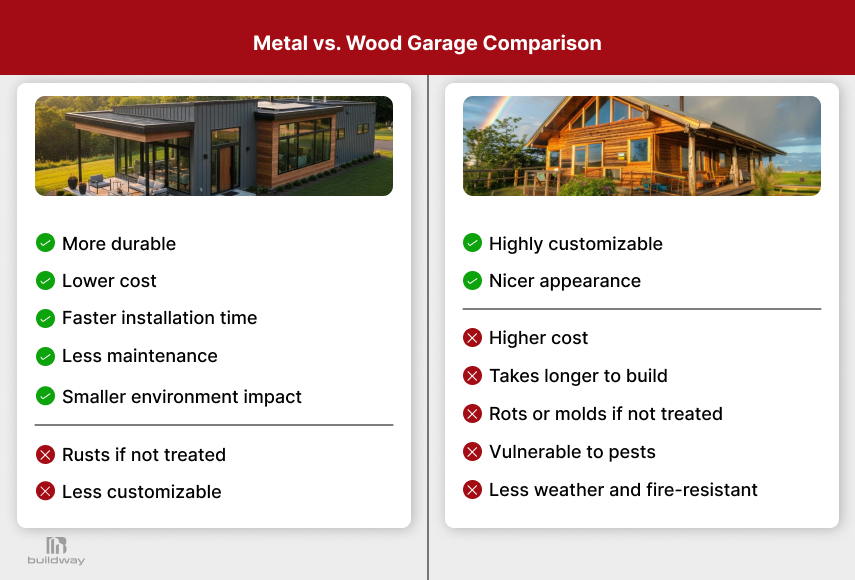

If longevity and low maintenance are your priorities, metal buildings are the clear winner in most environments. Here’s a side-by-side comparison of the most critical differences when evaluating a metal vs wood building lifespan and maintenance demands.

Metal Buildings

- Lifespan: 50-100+ years

- Strengths: Resistant to rot, pests, fire, and warping

- Maintenance: Minimal (occasional inspections and coating checks)

- Best for: Humid, coastal, fire-prone, or pest-heavy regions

Wood Buildings

- Lifespan: 30-80+ years

- Vulnerabilities: Moisture, termites, warping

- Maintenance: Frequent (painting, sealing, pest control)

- Best for: Dry, mild climates (with consistent care)

Metal buildings typically outlast wood with far less effort over time. While wood can be long-lasting, it demands more frequent maintenance to stay structurally sound.

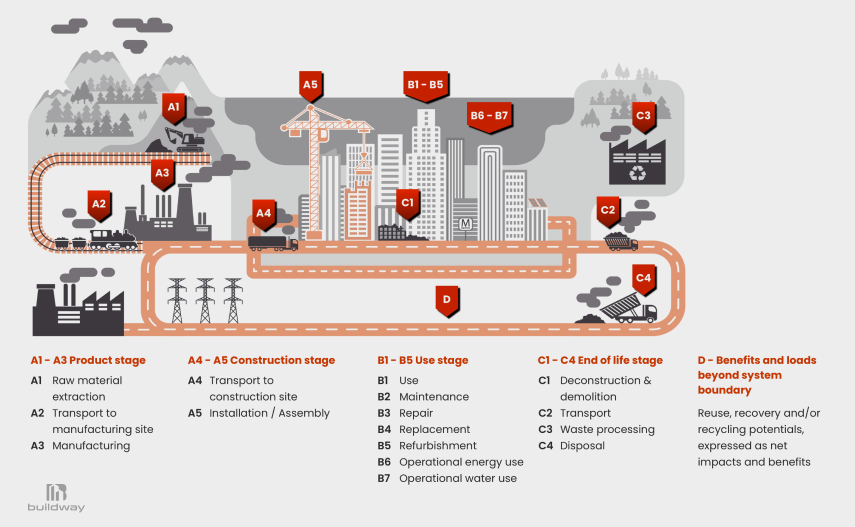

What Does “Building Lifespan” Actually Mean?

Before diving into comparisons, let’s define what we’re really talking about when we say “building lifespan.” Most people assume it means how long a building stands but in reality, there are several different interpretations:

- Design Life is how long the structure is engineered to last based on safety codes and expected loads.

- Service Life refers to how long the building can function properly with routine maintenance.

- Real-World Lifespan is the actual number of years the building stays usable, often longer than the design life when well-maintained.

A building isn’t a single entity, it’s a system of components. The frame, exterior envelope, and interior finishes each have different vulnerabilities. A structure might be standing after 60 years, but if the siding is rotted or the insulation soaked, it’s no longer functional without major repairs.

So when we ask “which lasts longer,” we’re really asking:

- How long can the structure remain safe?

- How often will major repairs be needed?

- What’s the total maintenance burden over decades?

With these definitions in mind, let’s explore how a metal vs wood building performs over time in real-world conditions.

Comparing the Real-Life Longevity of Metal vs Wood Buildings

Before choosing between a metal vs wood building, it’s important to understand how each material actually performs over time. Real-world lifespan depends on a lot of factors other than material itself. It’s shaped by climate, construction quality, and ongoing maintenance. Let’s take a closer look at how long metal and wood buildings typically last, and what factors can shorten or extend that lifespan.

1. Steel Building Lifespan: 40 to 100+ Years

Pre-engineered metal buildings (PEMBs) are designed for durability. In typical U.S. climates, a steel structure can last anywhere from 50-100 years or more, depending on maintenance, coatings, and climate exposure.

In fact, many steel-framed commercial buildings easily surpass 60–70 years of service life, especially when built with galvanized or coated steel. The steel itself doesn’t wear out, but corrosion and moisture buildup can lead to early failure if not addressed.

With proper planning and minor maintenance, steel buildings can easily outlive their design life.

What Impacts Steel Lifespan?

- Positive factors: Galvanization, weather-resistant coatings, good site drainage, proper insulation.

- Negative factors: Coastal salt exposure, trapped condensation, unsealed fasteners, poor ventilation.

Protective coatings play a massive role in long-term durability, especially in humid or coastal environments. For example, Galvalume Plus™ steel offers superior corrosion resistance compared to traditional painted panels, which directly impacts how long a metal building can realistically last.

2. Wood Building Lifespan: 30 to 80+ Years

Traditional wood-framed structures can also last a very long time: up to 80 years or more, especially when they’re detailed well and maintained consistently. We’ve all seen examples of century-old barns still in use.

However, wood is far more sensitive to environmental conditions and neglect. Moisture intrusion, termites, and a lack of maintenance are common culprits that drastically shorten the lifespan of wood-framed buildings.

While wood can match steel in some environments, it requires far more hands-on care to get there.

What Impacts Wood Lifespan?

- Positive factors: Pressure-treated lumber, raised foundations, vapor barriers, regular painting/staining.

- Negative factors: High humidity, persistent moisture, termites, unsealed joints, poor ventilation.

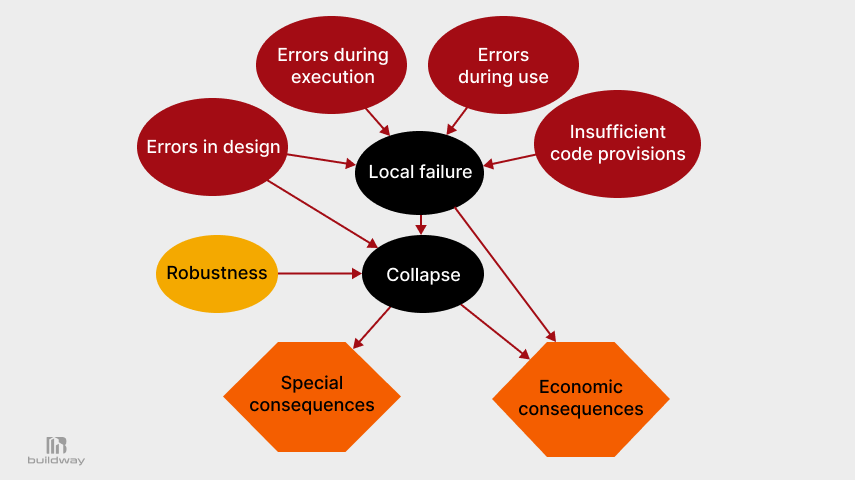

What Causes Buildings to Fail?

Understanding lifespan means looking beyond just the years a building stands, it’s about knowing what actually causes it to fail. Buildings rarely fail because the materials “expire.” Instead, they fail because a specific component deteriorates or a failure chain begins, often triggered by neglect.

That’s why it’s important to look at the most common failure points in each building type, what typically goes wrong first, and why.

How Steel Buildings Fail

While steel is known for its strength and longevity, it’s not indestructible. Most failures in metal buildings come from preventable issues, especially related to moisture and detailing, not the steel itself.

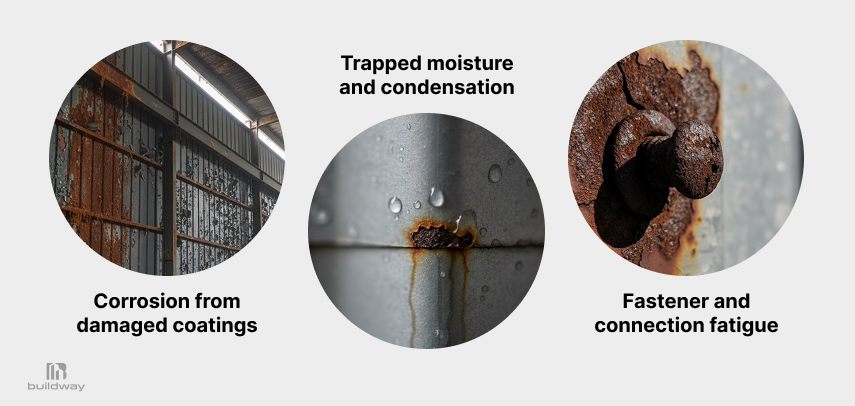

Common Failure Points in Steel Buildings:

- Corrosion from damaged coatings: Steel needs a protective layer like galvanization or paint to prevent rust. When that layer is scratched, punctured, or improperly applied, corrosion can begin.

- Trapped moisture and condensation: In most cases, condensation problems aren’t caused by the steel itself but by poor insulation and vapor control. Proper insulation design is critical not just for energy efficiency, but for preventing hidden moisture buildup that leads to long-term corrosion inside metal buildings.

- Fastener and connection fatigue: If bolts or screws are over-tightened, under-tightened, or poorly aligned, they can loosen over time. This leads to leaks, frame movement, or structural stress from thermal expansion.

Does Steel Rust?

Yes, but only when protective coatings are compromised and moisture is allowed to sit. With proper detailing, routine inspections, and condensation control, rust is preventable, even in humid or coastal environments.

How Wood Buildings Fail

Wood is a proven and capable building material, but its longevity depends heavily on keeping moisture under control. Most wood-building failures aren’t sudden, they develop slowly when water, pests, or movement go unchecked.

Common Failure Points in Wood Buildings:

- Rot from persistent moisture: When siding, roofing, or flashing allows water intrusion, wood framing can begin to rot. If the issue isn’t caught early, structural degradation can spread quickly.

- Termites and pest damage: In warm and humid regions especially across the Southeast, termites and carpenter ants pose a serious risk. Without routine inspections and preventative treatment, damage can remain hidden for years.

- Warping and shrinkage: Wood naturally expands and contracts with changes in humidity and temperature. Over time, this movement can lead to cracked finishes, misaligned doors, and structural stress.

Does Wood Rot if Properly Maintained?

No. Treated wood that stays dry can last for decades. However, once moisture becomes persistent, deterioration accelerates. In wood buildings, moisture control is the single most important factor for long-term durability.

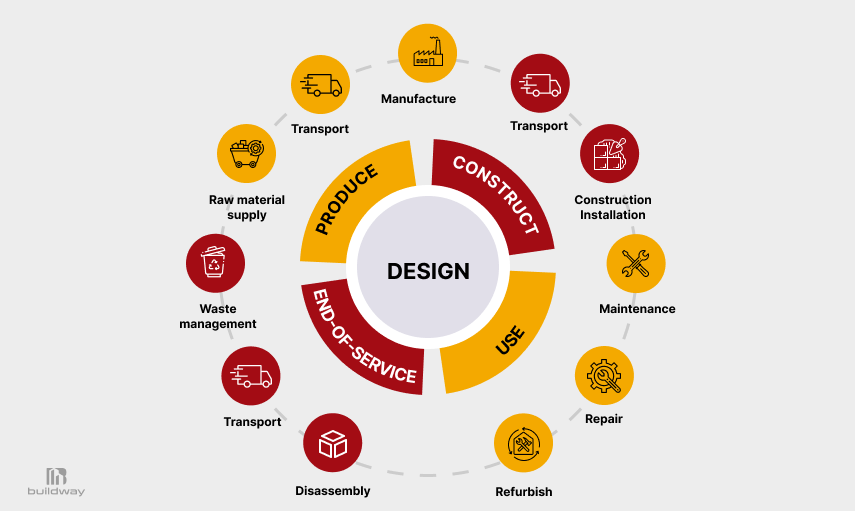

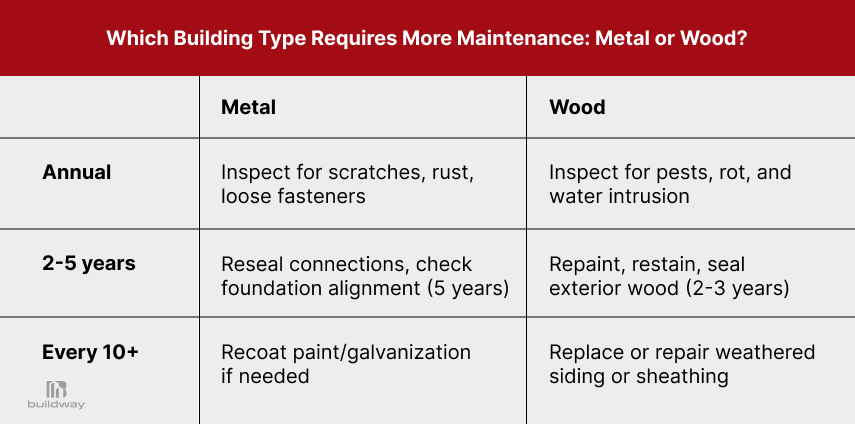

Which Building Type Requires More Maintenance: Metal or Wood?

There’s no such thing as a truly “maintenance-free” building regardless of material. However, the type, frequency, and cost of upkeep can vary dramatically between metal and wood structures. Understanding these differences is key to making the right long-term investment.

Metal Building Maintenance

Steel buildings require less frequent but essential inspections. Most maintenance revolves around keeping moisture out, sealing joints, and ensuring coatings are intact.

Common Tasks:

- Annual: Inspect for scratches, rust, loose fasteners

- Every 5 Years: Reseal connections, check foundation alignment

- Every 10+ Years: Recoat paint/galvanization if needed

When problems are addressed early, they’re usually easy and inexpensive to fix.

Wood Building Maintenance

Wood demands more frequent, hands-on care, especially if exposed to the elements. Paint or stain needs to be reapplied every 2–3 years, and pest control should be ongoing.

Common Tasks:

- Annual: Inspect for pests, rot, and water intrusion

- Every 2–3 Years: Repaint, restain, seal exterior wood

- Every 10 Years: Replace or repair weathered siding or sheathing

Neglecting wood maintenance even for a few years can lead to major structural issues.

Performance by Climate: What Lasts Longer Where?

Climate and environmental conditions have a major impact on how well a metal vs wood building holds up over time. Certain materials perform better in specific regions due to factors like humidity, wind, temperature swings, and fire risk. Below, we break down how metal and wood buildings compare across different U.S. climates and which is better suited for each environment.

1. High-Wind or Hurricane Zones

- Winner: Steel

- Steel buildings are engineered to resist wind uplift, racking, and lateral loads better than wood, especially when built to local codes.

2. Fire-Prone Areas (West, Southwest)

- Winner: Steel

- Metal is naturally non-combustible. It won’t ignite from embers or nearby flames, making it ideal for wildfire zones.

3. Humid & Coastal Climates (Southeast, Gulf Coast)

- Winner: Steel (with marine coatings)

- Steel can corrode in salty air, but only if unprotected. With coatings and drainage, it resists rot and termites far better than wood.

4. Cold & Snowy Climates (Northeast, Upper Midwest)

- Tied: Both need good vapor control

- In freezing climates, condensation inside the building is the enemy. Steel needs vapor barriers; wood needs air sealing and insulation to prevent rot or mold.

Metal vs Wood Building: Which Is More Cost-Effective Over Time?

While wood buildings often have lower upfront costs, they’re more expensive to maintain and typically require more frequent repairs. Steel buildings on the other hand, may cost more to install, but they save money over the long run with lower maintenance, longer component lifespans, and less risk of hidden damage.

Lifetime Cost Factors:

| Factor | Metal | Wood |

| Upfront Material Cost | Higher | Lower |

| Labor | Lower (prefab) | Higher (custom framing) |

| Maintenance | Low frequency | High frequency |

| Repairs | Less common | More frequent |

| Resale/Value Retention | Strong | Depends on condition |

When evaluating long-term value, looking at a metal vs wood building from both an installation and upkeep perspective is key.

Red Flags to Watch Out For: Before and After You Build

Even the best materials can fail prematurely if key issues are overlooked during design, construction, or maintenance. Whether you’re building with metal or wood, keeping an eye out for these red flags can save you thousands in repairs and years of building life.

Before and During Construction

- Inadequate Site Drainage: Poor water runoff near the foundation can damage both wood and metal over time.

What to Do: Ensure your site is graded for drainage and use gutters to divert water away from the base. - Skipping Ventilation or Vapor Barriers: Condensation inside a building especially in cold or humid areas, can impact insulation and materials if not managed correctly.

What to Do: Include proper roof and wall ventilation, and use vapor barriers as needed for your climate. - Using Unprotected or Incorrect Materials for the Region: In any structure, using untreated wood or non-galvanized steel in the wrong environment increases risk.

What to Do: Work with a reputable builder who selects region-appropriate materials and finishes from the start. - Poor Construction Detailing: Improper flashing, gaps at joints, or misaligned panels can lead to early wear in any building.

What to Do: Choose experienced installers who follow industry best practices for weatherproofing and connections.

During Ownership & Maintenance

- Rust Spots or Coating Damage (Metal): These are cosmetic or early signs of wear not structural issues, if caught early.

What to Do: Touch up scratches or worn areas with manufacturer-approved coatings during routine inspections. - Wood Rot or Pests (Wood): Moisture and insects are the most common threats to wood structures, especially in warmer climates.

What to Do: Maintain sealants and schedule pest control checks annually. - Frame Movement or Door Misalignment: This can occur in both wood and steel structures due to settling, foundation shifts, or poor site prep.

What to Do: Monitor high-stress areas (like corners and large doors) and contact a builder if issues appear.

These are common pitfalls that can impact the performance of any metal vs wood building, regardless of material quality.

Why This Matters

These aren’t material flaws, they’re preventable issues caused by improper installation, poor detailing, or lack of maintenance. At Buildway, we focus on climate-appropriate designs, corrosion-resistant steel, and precision-built structures to maximize longevity.

With smart planning and routine care, your building can easily exceed its expected lifespan, whether it’s steel, wood, or a hybrid.

Want Expert Help Reviewing Your Plans? Contact us or give us a call at +1 (855) 944-1515. Our team is here to walk you through what matters for long-term building performance in your region. No pressure, just practical advice from experienced steel building professionals.

Conclusion

There’s no one-size-fits-all answer when comparing a metal vs wood building, but here’s the clearest way to think about it:

- If you live in a harsh climate (wind, pests, moisture, fire), and want minimal maintenance, metal buildings have the edge in long-term durability.

- If you’re in a dry, mild climate, and you’re willing to invest in consistent upkeep, a well-built wood building can last just as long.

Lifespan Comparison Chart

| Material Type | Lifespan Range | Key Threats | Longevity Boosters |

| Steel | 40–100+ yrs | Corrosion, trapped moisture | Galvanization, sealants, drainage |

| Wood | 30–80+ yrs | Rot, pests, warping | Treated lumber, proper detailing |

Ultimately, the detailing, drainage, coatings, and maintenance matter more than the material itself.

Not sure which type of building is right for your climate and budget? Get our free 1-page checklist: Metal vs Wood: Which Lasts Longer in Your Climate?

It Includes:

- Lifespan estimates by region

- Maintenance planning tips

- Red flags to watch for

Still Have Questions? Let’s Talk! Not sure which building system fits your site, climate, or budget? Our team is happy to help you plan with confidence. Contact us today. OR

Call us today at +1 (855) 944-1515. We’ll walk you through your options: no pressure, just real answers from building professionals.

FAQs

1. How long do metal buildings really last?

Well-maintained metal buildings typically last 50 to 100+ years. Their longevity depends on protective coatings, site drainage, and whether moisture issues like condensation are managed properly. With minimal upkeep, steel structures often outlive their design life.

2. Are wood buildings durable enough for long-term use?

Yes, but only if they’re well-maintained. A wood-framed building can last 30 to 80 years or more when protected from moisture, regularly sealed or painted, and treated against pests. Without ongoing care, wood degrades faster than steel.

3. Do steel buildings rust over time?

Steel can rust, but only when its protective coating is damaged and moisture is allowed to sit. Rust is preventable with proper detailing, good drainage, and regular inspections. Interior rust is often caused by trapped condensation, especially in poorly insulated buildings.

4. Do wood buildings rot if they’re properly maintained?

No. Properly maintained wood doesn’t rot. The key is to keep it dry and sealed. Regular painting, staining, and moisture control prevent rot and extend the building’s service life significantly.

5. Which is easier to maintain: metal or wood buildings?

Metal buildings require less maintenance overall. They benefit from periodic inspections and coating touch-ups. Wood buildings, on the other hand, demand more frequent care like repainting, sealing, and pest control to maintain their integrity.

6. Is a metal building better in humid or coastal areas?

Yes. Steel is generally better suited for humid and coastal environments, provided it has corrosion-resistant coatings. Unlike wood, metal doesn’t rot or attract pests, making it a smart choice for damp, termite-prone regions.

7. Can a wood building last as long as a steel one?

It’s possible, but rare. Wood can match steel’s lifespan in dry climates if it’s consistently maintained. However, it’s more vulnerable to environmental damage, which is why steel tends to last longer with less effort.

8. What’s more cost-effective long-term: metal or wood buildings?

While wood often costs less upfront, metal buildings usually have a lower total cost of ownership. They require fewer repairs, last longer, and need less maintenance making them more cost-effective over 30–50 years.

9. What should I consider when deciding between a metal vs wood building?

Consider your climate, budget, and how much maintenance you’re willing to perform. A metal vs wood building comparison should focus on long-term durability, environmental suitability, and upfront vs ongoing costs.