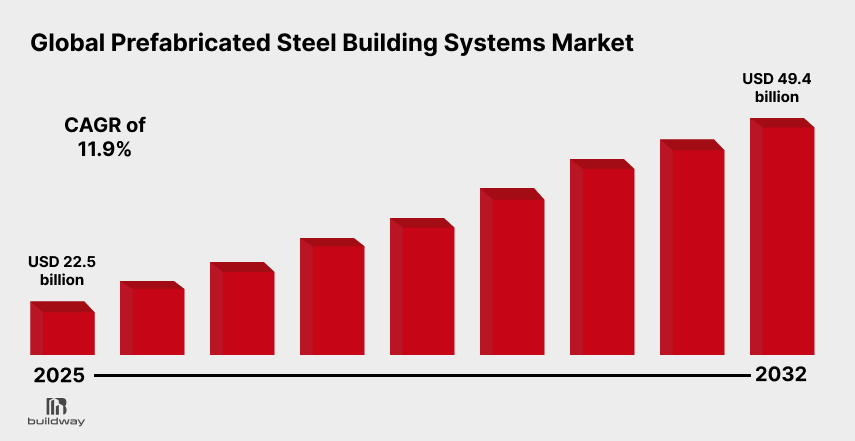

Metal buildings have come a long way from being simple, utilitarian structures. As we move toward 2026, steel construction is entering a new era: defined by smarter design, advanced materials, sustainability mandates, and digital intelligence. This transformation is backed by strong market momentum: the global metal building systems market is projected to grow from about USD 22.5 billion in 2025 to nearly USD 49.4 billion by 2032, at a CAGR of 11.9%, driven by demand for faster, more flexible steel construction.

What makes this shift especially compelling is that it’s already happening. These innovations are actively reshaping how metal buildings are designed, fabricated, and operated across industrial, commercial, and mixed-use projects.

In this blog, we’ll explore the most important metal building trends for 2026, explain what’s driving them, and most importantly, show why they matter for real-world projects. Whether you’re planning, designing, building, or investing, this is your roadmap to the future of metal construction.

Key Takeaways: Metal Building Trends 2026

- 2026 is a turning point for metal construction as labor shortages, sustainability pressure, and faster timelines push steel buildings into the mainstream.

- The market is growing fast, with global metal building systems nearly doubling by 2032, signaling strong long-term demand.

- Next-gen steel materials are making metal buildings lighter, stronger, and more durable with lower lifecycle costs.

- Sustainability is now essential, driven by recycled steel, embodied carbon tracking, and net-zero requirements.

- Prefabrication and modular construction are becoming standard, reducing risk, waste, and on-site labor needs.

- Digital tools, BIM, and AI are improving coordination, accuracy, and design efficiency.

- Smart metal buildings use sensors and IoT to enable predictive maintenance and energy optimization.

- Resilient design is critical, with metal buildings engineered for extreme weather, seismic activity, and climate stress.

Metal buildings in 2026 are faster to build, smarter to operate, more sustainable, and better prepared for the future.

Why 2026 Will Be a Pivotal Year for Metal Buildings?

By 2026, multiple industry forces are converging to reshape metal construction. Labor shortages, rising sustainability requirements, faster project timelines, and rapid digital adoption are accelerating the shift toward metal building systems. Together, these changes position 2026 as a defining year, when steel buildings move from an alternative option to a preferred, future-ready solution.

1. Post-Pandemic Construction Realities

The construction industry has permanently shifted its priorities. Owners now expect:

- Faster project delivery

- More predictable budgets

- Fewer on-site delays

Metal buildings, especially pre-engineered and prefab systems, naturally align with these expectations by reducing on-site complexity and construction time.

2. Ongoing Labor Shortages

Skilled labor shortages continue to affect contractors worldwide. As a result, the industry is accelerating toward:

- Automation

- Offsite fabrication

- Simplified assembly systems

Steel construction adapts extremely well to these methods, making metal buildings more attractive with every passing year.

3. Sustainability & Regulatory Pressure

Sustainability expectations are rising across the construction industry, and metal buildings are well positioned to meet them. Governments, investors, and corporate tenants are pushing for low-carbon, energy-efficient buildings making steel a long-term solution rather than a compromise.

Key drivers include:

- Stricter environmental and energy-efficiency regulations

- Increased investor focus on ESG performance

- Growing demand for net-zero and low-carbon facilities

- Steel’s recyclability, durability, and long service life

These shifts are accelerating adoption, reinforcing why steel buildings are increasingly viewed as the future of affordable construction.

Note: 2026 isn’t just another year of incremental change. It’s when metal buildings move fully into the mainstream as a future-ready construction solution.

Trend #1: Next-Generation Materials & Composite Alloys

Steel materials are evolving rapidly, and next-generation alloys are redefining what metal buildings can achieve. In 2026, stronger, lighter, and more durable materials are enabling faster construction, longer lifespans, and greater design flexibility.

1. Lightweight, High-Strength Steel

New steel grades offer significantly higher strength-to-weight ratios. This means:

- Less material without sacrificing performance

- Reduced foundation requirements

- Lower transportation and erection costs

These steels are particularly valuable for large-span buildings like warehouses, logistics centers, and industrial facilities.

2. Advanced Corrosion-Resistant Coatings

Coating technology is also advancing. New multi-layer and nano-based coatings dramatically improve resistance to:

- Moisture

- Salt air

- Industrial chemicals

For owners, this translates into longer building life cycles and reduced maintenance costs over decades.

3. Steel + Composite Material Systems

Hybrid systems that combine steel with materials like fiber-reinforced polymers (FRP) are gaining traction. These systems enhance:

- Structural efficiency

- Fire resistance

- Design flexibility

Why this trend matters: Stronger, lighter, and more durable materials allow teams to build smarter, not just bigger or cheaper.

Trend #2: Sustainable & Net-Zero Metal Buildings

Metal buildings are playing a central role in the shift toward net-zero construction. Advances in sustainable steel sourcing, energy-efficient systems, and low-carbon design are redefining what “green building” means in 2026.

1. Recycled Steel & Circular Construction

Steel is one of the most recyclable building materials in the world. In 2026, projects increasingly prioritize:

- High recycled-content steel

- Transparent supply chains

- Circular design principles

This reduces environmental impact without compromising structural integrity.

2. Embodied Carbon Tracking

Sustainability efforts are expanding beyond operational energy to include embodied carbon: the emissions generated during material production, transport, and construction. In 2026, digital assessment tools are helping teams measure this impact early in the design process.

Why embodied carbon tracking matters:

- Enables early comparison of low-impact steel options

- Supports informed, data-driven material decisions

- Helps meet sustainability benchmarks and net-zero targets

- Improves transparency for ESG reporting and certifications

By addressing carbon at the material level, metal buildings can significantly reduce their total environmental footprint.

3. Certifications & ESG Influence

Green building certifications such as LEED, along with ESG-driven investment strategies, are pushing metal buildings toward:

- Better thermal envelopes

- Energy-efficient roof and wall systems

- Renewable energy integration

Why it matters: Sustainable metal buildings aren’t just environmentally responsible, they’re increasingly required for permits, funding, and long-term value.

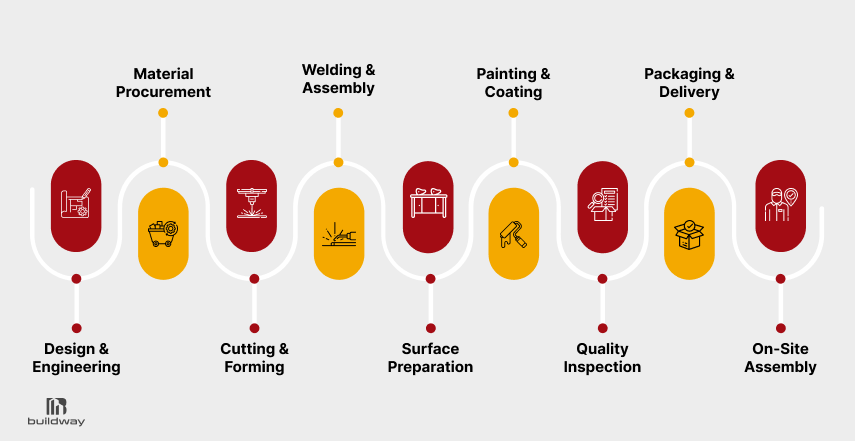

Trend #3: Prefab & Modular Tech Goes Mainstream

Prefabrication is reshaping metal construction by shifting more work offsite into controlled, highly efficient manufacturing environments. By 2026, it’s becoming a core strategy for faster delivery, higher quality, and lower project risk.

1. Advanced Offsite Fabrication

By 2026, most high-quality metal buildings rely heavily on offsite manufacturing. Controlled factory environments enable:

- Robotic welding and cutting

- Consistent quality control

- Minimal material waste

2. Faster Timelines, Lower Risk

Prefab metal buildings dramatically reduce on-site labor needs and weather-related delays. This leads to:

- Faster project completion

- Improved cost certainty

- Safer job sites

3. Scalability Across Sectors

What started in industrial construction is now common in:

- Commercial facilities

- Distribution centers

- Agricultural and institutional buildings

Ready to Build a Future-Ready Metal Building? See how modern prefab, smart design, and sustainable steel come together in real-world projects.

Explore Our Metal Building Projects

View Our Building Gallery

Trend #4: Digital Design, BIM & AI Integration

Digital tools are redefining how metal buildings are designed and coordinated. In 2026, BIM, AI-driven modeling, and data-led workflows are improving accuracy, collaboration, and project outcomes across steel construction.

1. BIM as a Standard Practice

Building Information Modeling (BIM) is now central to metal construction. It enables:

- Early clash detection

- Precise material coordination

- Seamless collaboration between teams

2. AI-Assisted Structural Optimization

AI tools are beginning to analyze:

- Load paths

- Material efficiency

- Energy performance

These systems help engineers arrive at optimized designs faster, reducing overengineering and cost.

Why it matters: Digital-first design leads to fewer surprises, fewer change orders, and better-performing buildings.

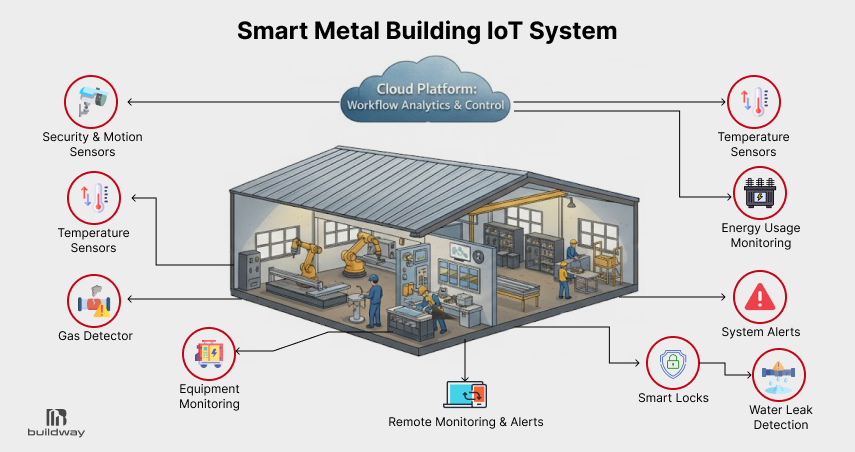

Trend #5: Smart Metal Buildings & Embedded Systems

Metal buildings are becoming smarter and more connected. By 2026, embedded sensors, IoT systems, and intelligent monitoring are transforming steel structures into data-driven, high-performance assets.

1. Embedded Sensors & IoT

Sensors integrated into steel structures can monitor:

- Structural stress

- Vibration

- Temperature and humidity

This data enables predictive maintenance, reducing downtime and extending building life.

2. Energy & Performance Monitoring

Smart metal buildings can automatically adjust:

- HVAC systems

- Lighting

- Power consumption

based on real-time occupancy and environmental data.

Why it matters: Buildings are no longer passive, they actively support efficiency, safety, and operational insight.

Trend #6: Resilient Designs for Extreme Climates

Climate resilience is becoming a core design priority. In 2026, metal buildings are increasingly engineered to withstand extreme weather, seismic activity, and temperature variability without sacrificing efficiency or cost control.

Metal buildings in 2026 are increasingly designed to perform under:

- Extreme wind events, including hurricanes, cyclonic storms, and high-wind regions

- Seismic activity, with improved ductility, load redistribution, and energy dissipation

- Wide temperature fluctuations, minimizing thermal stress, expansion fatigue, and envelope degradation

Advanced simulation and digital modeling tools enable engineers to test real-world scenarios early in the design phase. This allows structural systems to be fine-tuned for specific regional risks while keeping steel usage efficient and construction costs controlled.

Why it matters: Resilient metal buildings help protect occupants, maintain operational continuity during disruptions, and preserve long-term asset value as climate risks and regulatory expectations continue to rise.

What These Trends Mean for Industry Professionals

The metal building trends shaping 2026 are redefining how projects are planned, delivered, and managed across the entire construction ecosystem. Each stakeholder group stands to benefit in different ways, but those who adapt early will gain the strongest competitive advantage.

Here’s how these trends impact key industry roles:

- Architects & Designers: Greater design freedom through advanced materials, digital modeling, and performance-based tools allowing for more efficient, creative, and data-backed solutions.

- Fabricators & Manufacturers: Rising demand for automation, precision fabrication, and digital workflows, creating opportunities for higher productivity, consistent quality, and scalable operations.

- Contractors & Builders: Faster construction timelines, improved coordination through BIM, and fewer on-site uncertainties reducing risk, labor dependency, and costly delays.

- Owners & Developers: More durable, energy-efficient, and intelligent buildings that deliver long-term value, lower operating costs, and stronger resilience against future regulatory and climate pressures.

Understanding and responding to these trends early helps industry professionals make smarter decisions, future-proof their projects, and stay competitive in a rapidly evolving construction landscape.

What Comes After 2026 for Metal Buildings?

The pace of innovation in metal construction shows no signs of slowing after 2026. As digital tools, advanced materials, and automation continue to mature, metal buildings are expected to play a leading role in the next generation of construction systems. Their structural flexibility, durability, and compatibility with emerging technologies make them ideal platforms for future innovation.

Key developments on the horizon include:

- AI-driven generative design, enabling rapid exploration of optimized structural and material solutions

- Self-healing coatings and materials that extend building lifespan and reduce long-term maintenance

- Semi-autonomous construction workflows, combining robotics, automation, and human oversight

As these technologies become more commercially viable, metal buildings are uniquely positioned to integrate them quickly supporting safer construction, lower lifecycle costs, and more adaptive built environments.

Turn 2026 Trends Into Your Next Project.

The metal building trends shaping 2026 are already here and the right partner makes all the difference. For those planning a project, understanding how to choose the right steel building kit in 2026 is just as important as tracking industry trends. Whether you’re planning a new facility, expanding an existing one, or exploring prefab steel solutions, our team can help you design and deliver a future-ready metal building.

Request a Quote for Your Next Project

Contact Our Team for More Details

FAQ’s

1. What are the top metal building trends for 2026?

The top metal building trends for 2026 include:

- Next-generation high-strength steel materials

- Sustainable and net-zero metal building design

- Prefabricated and modular construction systems

- BIM, AI, and digital design integration

- Smart metal buildings with embedded IoT technology

These trends focus on faster construction, lower environmental impact, and smarter building performance.

2. How is steel construction changing in 2026?

Steel construction in 2026 is becoming more lightweight, automated, and data-driven. Advances in steel alloys, robotic fabrication, BIM coordination, and AI-assisted design allow projects to be built faster, with less waste and greater precision than traditional construction methods.

3. What new materials are used in modern metal buildings?

Modern metal buildings use:

- High-strength, lightweight steel alloys

- Advanced corrosion-resistant steel coatings

- Steel-composite systems such as steel combined with fiber-reinforced polymers (FRP)

These materials improve durability, reduce maintenance, and extend building lifespan.

4. Are metal buildings environmentally friendly?

Yes. Metal buildings are environmentally friendly because steel is 100% recyclable, highly durable, and compatible with energy-efficient and net-zero building systems. When designed properly, metal buildings can meet or exceed green building standards like LEED.

5. Is steel construction becoming more sustainable?

Steel construction is becoming more sustainable through:

- Increased use of recycled steel

- Embodied carbon tracking

- Longer building life cycles

- Reduced material waste through prefabrication

These factors make steel one of the most sustainable structural materials available.

6. How is prefabrication changing metal construction?

Prefabrication changes metal construction by moving most fabrication offsite into controlled factories. This results in:

- Faster build times

- Higher quality control

- Less on-site labor

- Reduced construction waste

Prefab metal buildings are now common across industrial, commercial, and logistics projects.

7. Are prefab metal buildings worth it?

Prefab metal buildings are worth it for many projects because they offer shorter timelines, cost predictability, and consistent quality. They are especially effective for warehouses, industrial facilities, and large-span structures.

8. What are smart metal buildings?

Smart metal buildings are steel structures that integrate sensors, automation, and digital monitoring systems. These systems track structural health, energy usage, and environmental conditions in real time, enabling predictive maintenance and improved efficiency.

9. Can metal buildings support smart technology?

Yes. Metal buildings are ideal for smart technology because their structural systems easily accommodate IoT sensors, energy management systems, and automation platforms during design and fabrication.

10. How is BIM used in metal construction?

BIM is used in metal construction to:

- Coordinate structural, architectural, and MEP systems

- Detect design clashes before construction

- Optimize steel fabrication and material use

- Improve collaboration across project teams

In 2026, BIM is a standard requirement for most metal building projects.

11. What problems do people report about metal buildings?

Common concerns include insulation, condensation, and noise—but these issues are typically caused by poor design or low-quality construction, not metal buildings themselves. Proper engineering and modern insulation systems resolve most problems.

12. What is the future of metal buildings beyond 2026?

Beyond 2026, metal buildings are expected to incorporate:

- AI-generated design optimization

- Self-healing coatings

- Greater automation in fabrication

- Fully connected smart building systems

Metal buildings are positioned to lead the future of construction innovation.