If you’re planning to invest in a steel building kit, choosing the right supplier accreditation is everything. Some metal buildings follow rigorous industry standards and accreditation processes, while others cut corners: risking your time, money, and safety.

Over the years, we’ve seen firsthand how costly it can be to choose the wrong supplier: delays, poor engineering, or even structural failures. This blog is here to help you vet a metal building kit manufacturer properly with plain-English explanations, a clear checklist, and real-world insights.

Why Supplier Accreditation Matters?

Choosing the right metal building supplier is about protecting your project from delays, code issues, and structural risks. Vetting a supplier ensures you’re working with a company that delivers safe, compliant, and well-engineered buildings. At Buildway, we’ve seen how cutting corners in this step can lead to costly problems down the line. Done right, vetting becomes your insurance policy, helping you build with confidence from the very start.

The Risks of Choosing Poorly

Without proper checks, you might end up with:

- Substandard steel that rusts early or buckles under load

- Incorrect engineering for your region’s snow, wind, or seismic requirements

- Non-compliance with local building codes, causing delays or denied permits

- Limited or no warranty if things go wrong

At Buildway, we’ve worked with clients who came to us mid-project frustrated, over budget, and dealing with problems caused by a supplier who failed to deliver what was promised. In many cases, the root issue wasn’t just poor service, it was how the building was originally designed and fabricated. Steel building kits are inherently strong and durable when they’re engineered to proper standards and produced under strict quality controls. This is exactly why well-designed steel building kits perform better over time, and why weaker, poorly engineered systems are far more likely to fail.

How Supplier Accreditation Helps You: That’s where accreditation steps in. Independent accreditations like AC472 and AC478 verify that manufacturers and assemblers meet strict engineering, fabrication, and quality standards. Think of them like a third-party quality seal: proof that your supplier can actually deliver a compliant, safe, and durable structure.

Key Supplier Accreditations to Check

When choosing a metal building supplier, the very first question you should ask is simple but critical: Are you accredited? Not just accredited in name, but backed by the right industry-recognized certifications. Selecting a supplier without verifying this foundation exposes your project to unnecessary risk, cost overruns, and performance failures.

Metal Building Systems Accreditation (AC472)

AC472 is a certification issued by the International Accreditation Service (IAS). It verifies that a manufacturer follows stringent quality control for metal building systems, including engineering design, materials, and fabrication processes.

Why It Matters:

- Ensures the structural components (frames, panels, bolts) are manufactured to code

- Includes third-party audits and inspection of factory operations

- Tied to IBC Chapter 17 of the International Building Code (IBC), which governs special inspections

In short, AC472 tells you the steel building is engineered and built correctly from the ground up.

Metal Building Assembly Supplier Accreditation (AC478)

AC478, on the other hand, focuses on the erectors: the people who actually assemble the building kit on-site.

Why It Matters:

- Ensures the team building your structure is trained, supervised, and compliant

- Covers project management, safety practices, and on-site quality checks

- Differentiates between a factory making the parts and a team assembling them properly

At Buildway, we always verify that both the manufacturer and the installer follow accredited processes, because even perfectly engineered steel can fail if it’s assembled poorly.

Additional Important Supplier Accreditations for Metal Building

While AC472 (for manufacturers) and AC478 (for erectors) are the most critical accreditations in the metal building industry, there are a few other important certifications and affiliations that can add credibility, ensure compliance, and reduce project risk. Here are some worth looking for:

- IAS AC473 (Cold-Formed Steel Component Manufacturers): This accreditation applies to companies that manufacture cold-formed steel components (like wall studs and light-gauge framing). If your building includes light-gauge elements, this certification ensures they’re produced under a verified quality control system.

- AISC Certification (American Institute of Steel Construction): AISC certifies structural steel fabricators and erectors. Their certification focuses on quality assurance, safety, and documented procedures. It’s especially relevant for complex or larger commercial steel structures.

- MBMA Membership: Metal Building Manufacturers Association: While not an accreditation, MBMA membership signals that a manufacturer participates in ongoing industry research and follows best practices. Members often help shape building standards and stay current with code changes.

- IAS ISO/IEC 17065 Accreditation: This accreditation is held by organizations that certify products, processes, or services. It adds an extra layer of trust when paired with AC472 or AC478, ensuring the certifying body itself meets international standards for impartiality and competence.

- UL Certification (Underwriters Laboratories): UL testing and certification on components (like insulation, coatings, or fire-rated assemblies) ensures materials meet safety and performance standards. While not specific to entire buildings, it’s a strong sign of product quality.

- ISO 9001: Quality Management Systems: ISO 9001 certifies that a company follows consistent quality management practices. While not specific to metal buildings or engineering, it can indicate operational discipline, especially useful when paired with industry-specific accreditations like AC472.

Note: While these accreditations support a supplier’s credibility, AC472 and AC478 remain the most essential for verifying engineering integrity and on-site assembly quality in pre-engineered metal buildings.

Supplier Accreditation Checklist

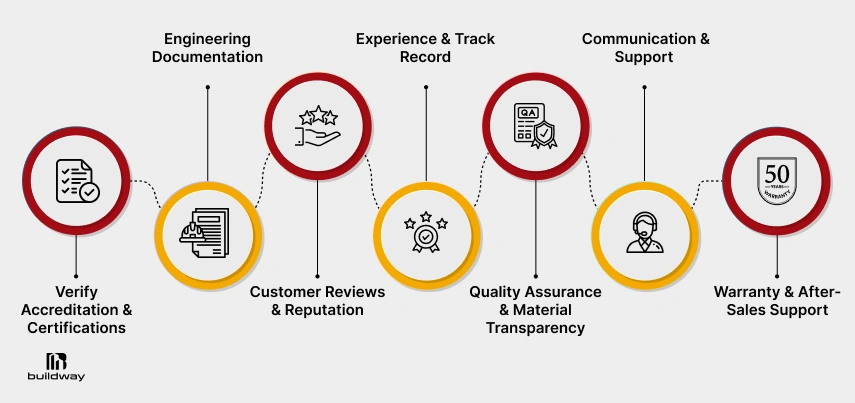

Choosing a metal building supplier can make or break your metal building project. At Buildway, we use this exact 7-step vetting process when assessing vendors and we recommend every buyer do the same. This checklist helps you avoid costly mistakes and ensures your supplier is truly qualified to deliver a safe, code-compliant, and durable structure.

1. Verify Accreditation & Certifications

- Ask for AC472 (manufacturer) and AC478 (installer) credentials

- Request certificate numbers and verify them with IAS (they’re publicly listed)

- Watch for fake logos. Always confirm independently

2. Engineering Documentation

You should receive:

- Stamped structural drawings by a licensed engineer

- Confirmation of wind, snow, and seismic loads for your exact location

- Clear local code compliance documentation (especially important in permit-heavy states)

If you’re told “it’s standard for all buildings”. That’s a red flag.

3. Customer Reviews & Reputation

- Search forums, Google reviews, and trade sites for real feedback

- Ask for project references, and call them, especially if you’re investing over $20K

- Be wary of overly generic testimonials or missing photos

4. Experience & Track Record

- Look for 5+ years of consistent operation under the same brand

- Review past project photos. Does their work align with your goals?

- At Buildway, we maintain a portfolio of completed builds by region and type, and so should your supplier

5. Quality Assurance & Material Transparency

- Ask for mill certificates (these confirm the steel grade and origin)

- Ensure they follow in-house QA checks or third-party inspections

- Check if they disclose coating specs. Rust-through warranties depend on this

6. Communication & Support

- Gauge their response time during quoting, delays now mean delays later

- Proposals should clearly explain:

- What’s included (frame, fasteners, insulation?)

- What’s not (foundation, erection, permits?)

- If they’re evasive or vague. Proceed with caution

7. Warranty & After-Sales Support

- Request documentation for:

- Frame warranty (often 20–50 years)

- Paint or rust-through guarantees

- Understand what’s required to keep the warranty valid

Long-term warranties may look impressive on paper, but their real value depends on the fine print and enforceability. To understand what a robust, well-structured warranty should include and what red flags to watch for, it’s worth reviewing a real-world example, such as this in-depth breakdown of a 50-year steel building warranty provided by Buildway.

Case Examples: Applying the Checklist

Understanding the vetting process is one thing, seeing how it plays out in real projects is another. Here are a couple of anonymized, real-world examples from our experience at Buildway that show exactly why following the checklist matters. These cases highlight what can go right and wrong, depending on the supplier you choose.

Case 1: AC472‑Accredited Manufacturer vs Non‑Accredited Supplier

A client reviewing two similar metal building quotes was tempted by a lower price from a non‑accredited supplier. On paper, both offers looked comparable, but the difference showed up quickly once permitting began.

What went wrong:

- Engineering documents were incomplete and not fully code‑compliant

- Local permit reviewers requested revisions and additional calculations

- The approval process was delayed by nearly four weeks

Outcome: The client ended up paying more for third‑party corrections and lost time than the original savings. The AC472‑accredited option would have passed permitting the first time.

Case 2: Strong Engineering, Weak Communication

In this case, the supplier provided solid, location‑specific engineering that met code requirements. However, communication issues surfaced once the building shipped.

What went wrong:

- Slow responses during shipment coordination

- Missing components discovered on delivery

- No clear ownership of the issue or resolution timeline

Outcome: The project stalled for almost two months while parts were reordered. Even with good engineering, poor communication caused costly delays.

Accreditation protects your structure, but communication and service protect your timeline. A successful metal building project requires both: strong credentials and a supplier who stays responsive from quote to completion.

Common Supplier Accreditation Mistakes to Avoid

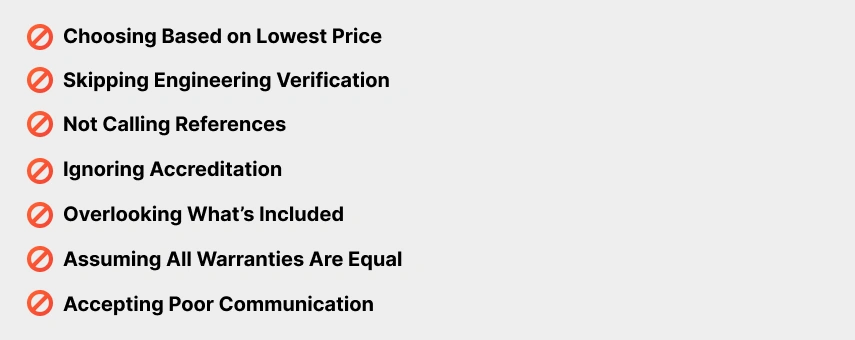

Even with the best intentions, buyers often make critical mistakes when choosing a metal building supplier. These missteps can lead to delays, added costs, or structural issues. Here are the most common ones to avoid, with short explanations based on real project experience at Buildway:

- Choosing Based on Lowest Price: Cheap kits often leave out key elements like certified engineering or code-specific loads. You might save upfront but pay later in redesigns, delays, or failed inspections.

- Skipping Engineering Verification: Assuming “standard engineering” is good enough is risky. Always confirm stamped drawings meet local code, including wind, snow, and seismic requirements.

- Not Calling References: Online reviews aren’t enough. Talk to real past clients. Ask about delivery timelines, communication, and any post-sale issues.

- Ignoring Accreditation: Suppliers without AC472 or AC478 are not held to third-party quality standards. Without this, you carry all the risk if things go wrong.

- Overlooking What’s Included: Some kits appear cheaper because they exclude critical items like fasteners, framed openings, or insulation. Always check what’s actually in the quote.

- Assuming All Warranties Are Equal: Not all warranties cover the same issues, some are limited or require specific maintenance. Read the fine print and ask questions.

- Accepting Poor Communication: If a supplier is slow to respond before the sale, expect worse after. Timely, clear support is a major indicator of reliability.

Avoiding these common mistakes puts you in control of your build, protecting your timeline, budget, and peace of mind.

Conclusion & Next Steps

Vetting a metal building kit manufacturer might feel overwhelming, but doing it right saves money, stress, and time. Accreditation, documentation, and experience matter more than price alone.

Want to make this easy? Download our Metal Building Supplier Accreditation Checklist. The same one we use at Buildway when reviewing vendors.

- Download the Metal Building Supplier Vetting Checklist (PDF)

- Need help reviewing a quote or checking supplier credentials? Get Expert Help Vetting Your Supplier.

Comparison Table: Accredited vs Non-Accredited Suppliers

| Criteria | Accredited (AC472 / AC478) | Non-Accredited |

| Engineering Documents | Stamped, code-compliant | Often incomplete or generic |

| Quality Assurance | Audited QA processes | Varies widely |

| Warranty Coverage | Transparent & enforceable | Limited or unclear |

| Compliance with IBC | Verified via third-party | Requires extra checks |

| Supplier Accountability | Certification-based oversight | Buyer bears full responsibility |

FAQ’s

1. How do I know if a metal building supplier is reliable?

A reliable metal building supplier will have AC472 accreditation, which confirms they meet strict engineering and quality standards. You should also look for clear and responsive communication, detailed engineering documentation, and verifiable project references. If a supplier dodges questions, delivers vague quotes, or can’t provide credentials, that’s a red flag.

2. What certifications should a metal building manufacturer have?

The most important certification is AC472, issued by the International Accreditation Service (IAS). This accreditation ensures the manufacturer follows consistent, code-compliant engineering, fabrication, and quality assurance processes. If the same company is handling the building erection, they should also have AC478, which covers site work, safety, and installation standards.

3. Is ISO certification enough?

ISO certification only applies to general business practices and management systems. It doesn’t prove that the buildings are engineered or fabricated to meet safety codes. For structural reliability and compliance, AC472 is far more relevant and trustworthy when evaluating metal building manufacturers.

4. Who is responsible for local code compliance?

While the manufacturer provides the required documents, such as stamped engineering drawings and load calculations. It’s ultimately up to you or your builder to ensure those plans meet your local building code. At Buildway, we help clients understand their regional requirements and make sure the documentation aligns with what local permit offices expect.

5. Do building installers or erectors need to be accredited?

Yes, installers should have AC478 accreditation to ensure proper on-site practices. Even a perfectly engineered metal building can become unsafe or non-compliant if it’s assembled incorrectly. AC478 verifies that the installation team follows standardized procedures, uses proper supervision, and maintains a safe, well-managed job site.

6. Can I use a generic building kit and adjust it myself?

Using a generic or off-the-shelf building kit without local engineering is risky. Each structure must be designed to handle the specific wind, snow, and seismic loads of your region. If you adjust it yourself or skip proper engineering, you might fail inspection or end up with a structure that’s unsafe, which can be costly to fix or replace later.

7. What happens if I choose a non-accredited supplier?

Choosing a non-accredited supplier means you’re taking on more risk, often without realizing it. There’s no third-party verification that the engineering is correct, the steel quality is consistent, or that the fabrication follows code. Clients who go this route frequently face delays, extra costs for rework, and in worst cases, structural failure. Accreditation is your protection.

8. How can I verify a supplier’s accreditation?

You can verify AC472 and AC478 accreditations by searching the company name or certificate number on the official IAS website. If a supplier claims to be accredited but refuses to share their certificate or number, that’s a warning sign. Legitimate companies are happy to provide proof.

9. Does Buildway only work with accredited suppliers?

Yes, Buildway only partners with manufacturers and installers who hold AC472 and/or AC478 accreditation. We’ve seen too many projects suffer from poor documentation, bad steel, or communication breakdowns when accreditation was ignored. We insist on working with credentialed partners so our clients don’t get burned down the road.