With steel construction becoming more popular than ever, it’s easy to assume the process is quick and simple: pick a design, get a quote, and you’re done… right? Not quite. The U.S. pre-engineered metal building market was valued at nearly $13 billion in 2024 and it’s projected to more than double over the next decade, reaching $27+ billion by 2033, thanks to rapid growth in commercial, industrial, and warehouse construction.

But as demand rises, so do metal building kit buying mistakes. Small mistakes like zoning issues, permit delays, or delivery problems can quickly derail your timeline or blow your budget. So how do you avoid those headaches before they happen? In this guide, we’ll walk you through the most common mistakes people make when buying a steel or metal building kit and exactly how to sidestep them. Let’s get started.

But, before you sign anything, download our Metal Building Kit Buying Checklist. It walks you through every critical step, from site prep and permitting to insulation and delivery coordination.

1. Clarify Your Purpose and Future Needs

One of the most common (and costly) mistakes first-time buyers make is thinking only about today’s needs. But a metal building is a long-term investment and if you don’t plan ahead, you could find yourself boxed in by size limits, access issues, or expensive retrofits down the road.

Here’s how to get it right from the start:

- Define current vs. future use: Ask yourself: what will this building need to accommodate in 5 or 10 years? Whether it’s storage, workshop, office, or agricultural use, your intended purpose affects layout, insulation, door height, and more.

- Choose the right size and configuration: Many buyers choose a smaller, cheaper size now, then quickly regret it when expansion costs double later. The trick is to plan for growth: add extra length or clear-span space now.

- Don’t overlook doors, windows, and height: Clearance for vehicles, mezzanine additions, or cranes matters. Once the steel is fabricated, changes are costly or impossible.

If you’re still weighing which size, layout, or configuration fits your long-term goals, our Steel Building Kit Buyer’s Guide for 2026 breaks down the key factors like dimensions, loads, clear-span options, and future expansion, so you don’t lock yourself into the wrong structure.

2. Check Local Codes, Zoning & Permits

Nothing brings a building project to a screeching halt like red tape. Many eager buyers jump straight into design and ordering, only to discover too late that their plans violate local zoning laws, HOA rules, or regional building codes. These oversights can lead to expensive delays, redesigns, or worst-case scenario: being denied the ability to build altogether.

Before you get too far ahead, make sure you’ve covered these essentials:

- Understand zoning and HOA rules: Even rural areas can have restrictions on building type, color, or setback. Always verify with local authorities.

- Meet building codes for your region: Wind, snow, and seismic loads differ by area. Ensure your kit meets local engineering standards.

- Start your permit process early: Permits often take weeks. Don’t order until your plans and permits are approved. Otherwise, you risk delays or redesign costs.

3. Site Preparation & Foundation: The Hidden Costs

Many first-time buyers get so focused on the building kit itself that they overlook what it’s actually sitting on. But your foundation and site conditions are just as critical and skipping steps here can lead to structural issues, costly fixes, or delays that stall your entire project.

Before you pour a single inch of concrete, make sure you’ve nailed down these essentials:

- Soil testing and drainage: A level, well-drained site prevents cracking, shifting, and corrosion. Invest in proper soil testing and grading.

- Don’t pour your slab before final plans: This is one of the most common and costly errors. Your anchor bolts and slab specs must match the engineered drawings. Before you pour your slab or finalize your plans, take 3 minutes to see what real builders have encountered on the ground and how to avoid those same pitfalls.

- Anchor bolts and foundation compatibility: Confirm bolt patterns, slab thickness, and edge distances before any concrete is poured.

Avoid Foundation & Site Surprises with a Pre-Engineered Solution. At Buildway, every structure is engineered to your site’s specs including anchor bolt layouts, foundation plans, and load certifications.

- Engineered drawings included

- Local code compliance guaranteed

- Expert support from planning to delivery

Get an instant quote now and ensure your foundation and building fit perfectly.

4. Understand What’s Included in the Quote & Total Cost

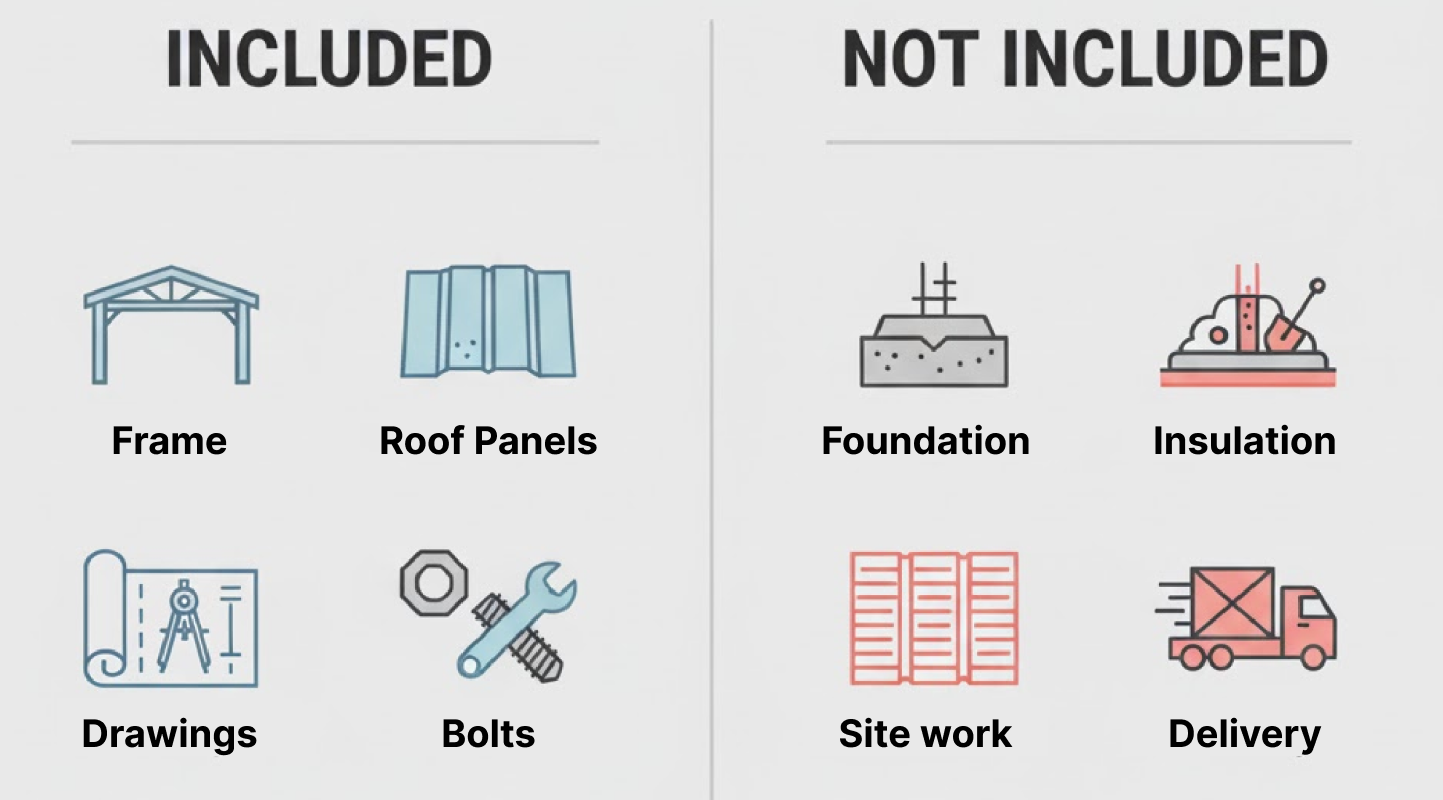

A metal building quote might look straightforward at first glance, but what’s included (or not) can vary drastically between suppliers. If you don’t dig into the details, you could end up facing unexpected costs or discover key components missing after your order is placed.

Before you commit, make sure you’ve reviewed everything line by line:

- Get an itemized quote: Confirm what’s included: framing, trim, fasteners, drawings, and insulation.

- Watch for hidden extras: Delivery, unloading, custom cuts, or insulation are often billed separately. Ask upfront.

- Cheapest isn’t best: Lower bids may mean thinner steel, weaker warranties, or missing components that you’ll pay for later. The Cheapest Bid Usually Costs More Later.

“Most PEMB buyers don’t realize that the cheapest bid often means more work (and cost) later.” — Reddit

Pro tip: Calculate total cost of ownership (kit + delivery + foundation + erection + finishing).

Beware of Red Flags and Misleading Deals

Reddit users often warn about sales pitches that promise unrealistic timelines or “too-good-to-be-true” discounts that disappear overnight. One buyer shared:

“The level of bullshit I got from the sales people was next-level.”

To be clear we’re not talking about genuine clearance pricing or limited inventory promotions that are backed by transparent specs and documentation. Those are legitimate ways to save.

The red flags are offers that sound unrealistically cheap, vague on details, or pressure you to sign immediately without providing full drawings, load ratings, or warranty terms. Always make sure you’re comparing the same specs, materials, and engineering quality before making a decision.

What to watch for:

- Unrealistic delivery promises

- Discounts with same-day sign requirements

- Vague or missing written details in quotes

How to avoid it:

- Ask for all specs and warranty terms in writing

- Don’t pay deposits without a contract

- Get at least 3 quotes from verified suppliers

Pro Tip: Ask each supplier to clearly separate kit costs from site prep, permits, and installation so you understand your true total project cost.

5. Material Quality, Engineering & Manufacturer Credibility

Not all metal building kits are built to the same standard and the lowest price often comes with hidden compromises in material strength, structural integrity, and long-term durability. Choosing a trusted, well-reviewed manufacturer with proven engineering standards is just as important as choosing the right building size or layout.

Before you commit to a supplier, do your homework on these key factors:

- Steel grade and gauge matter: Thinner, low-grade steel can fail under load. Always request specs on steel gauge and galvanization.

- Check for in-house design and engineering: Suppliers who handle design, fabrication, and engineering internally deliver better quality control and accountability.

- Verify warranty, references, and reviews: Search independent reviews and request references. Beware of vague warranties or unverified suppliers.

6. Insulation, Energy Efficiency & Future Adaptation

It’s easy to focus on the structure itself, but what’s inside and how your building will perform over time matters just as much. Too many buyers skip insulation or delay HVAC planning, only to face rust issues, uncomfortable conditions, and expensive retrofits later.

The key to future-proofing your building is planning smart from day one. Here’s how:

- Skipping insulation: Condensation, rust, and high energy bills often result from uninsulated buildings. Plan insulation and vapor barriers from day one.

- Plan HVAC and climate control early: If you’ll add heating, cooling, or machinery later, build in those needs now.

- Design for flexibility: Choose configurations that allow for future expansion or retrofits without major structural changes.

7. Delivery, Scheduling & Coordination

A perfectly designed building kit won’t help you if your site isn’t ready, permits are still pending, or your crew isn’t available. Lack of coordination is one of the biggest reasons projects fall behind or rack up unexpected costs.

To avoid unnecessary delays, be sure these critical steps are handled well in advance:

- Coordinate delivery timing: Never schedule delivery before your site and foundation are 100% ready.

- Inspect components immediately: When the kit arrives, verify all parts and hardware. Missing items delay installation.

- Account for permit or contractor delays: A delayed permit or busy installer can throw off your schedule. Plan buffer time.

What Questions Help You Avoid Metal Building Kit Buying Mistakes?

Finalizing your building kit without asking the right questions is like buying a car without lifting the hood. Many buyers assume that key details are “standard,” only to discover that critical components, site compatibility, or engineering requirements were left out.

A few well-placed questions can help you avoid surprise costs, construction delays, and long-term regrets. Ask these questions to any metal building supplier and don’t move forward until you have clear, written answers.

1. Zoning & Site Compliance

Before anything else, confirm that your land allows for your intended use.

- Is my property zoned for this type of structure?

- Are there any setback, height, or aesthetic restrictions from zoning or HOA rules?

- What permits will I need to secure before building can begin?

2. What’s Included in the Quote?

Make sure you’re comparing apples to apples when reviewing quotes.

- Does the quote include engineered foundation specs, anchor bolts, and structural drawings?

- Is insulation included, or is it an optional upgrade?

- Are fasteners, trim, doors, windows, and framing hardware part of the package?

Tip: Ask for a fully itemized quote to understand what’s included and what’s not.

3. Engineering & Load Requirements

Your building must meet local climate and code requirements.

- What wind, snow, and seismic loads is the structure engineered to handle?

- Is this engineering certified for my county or municipality?

- Can I review stamped engineering drawings before ordering?

4. Total Cost & Logistics

Get a true understanding of what you’ll pay, not just what’s advertised.

- What’s the all-in cost, including delivery, taxes, and unloading fees?

- Is erection (assembly) included, or do I need to hire a local contractor?

- Are there any other “hidden” fees I should expect (like custom colors, crane rental, or site prep costs)?

5. Warranty, Lead Time & Manufacturer Credibility

Make sure you’re working with a reputable supplier that stands behind their product.

- What is your warranty and what does it actually cover?

- What’s your average lead time from order to delivery?

- Do you have customer references I can speak with or recent reviews I can check?

Download your free “Metal Building Kit Buying Checklist”. Print it and tick each box as you finalize your order.

Conclusion & Next Steps

Buying a metal building kit can be a highly rewarding investment, when it’s done right. The key isn’t just choosing a building that fits your needs today, but one that will serve you well for years to come. By planning ahead, verifying every detail, and choosing quality over shortcuts, you’ll avoid the most common metal building kit buying mistakes that cost time, money, and peace of mind. The more intentional you are upfront, the smoother your project will go.

Not sure if you’re missing something before you order your metal building kit? With so many moving parts, it’s easy to overlook a small detail that turns into a big (and expensive) problem later.

Download our Free Metal Building Kit Buying Checklist to make sure you’ve covered every critical step including zoning, engineering, insulation, delivery coordination, and more. Then, schedule a free consultation with our team to walk through your plans, get expert input, and avoid costly surprises.

If you’re wondering what the process looks like after you request a quote, we break it down step-by-step in What Happens After You Request a Quote from Buildway? It shows you exactly what to expect from engineering to delivery.

Frequently Asked Questions

1. Can I erect a metal building kit myself?

Yes, many metal building kits are designed with DIY installation in mind. However, you’ll need the right tools, a capable crew, and a clear safety plan. For larger or more complex buildings, hiring professional installers is often the safer and more efficient choice.

2. Do I need a permit for a metal building?

In most cases, yes. Nearly all local jurisdictions require permits for metal buildings. Your engineered drawings will need to be reviewed and approved by your local building department before construction can begin.

3. What hidden costs should I expect with a metal building kit?

Common hidden costs include site preparation, foundation work, insulation, utility hookups, and equipment rental for unloading or erection. These are usually not included in the base kit price, so it’s important to factor them into your budget early on.

4. Is the cheapest metal building kit a good deal?

Usually not. Lower-priced kits often come with compromises such as thinner steel, missing components, vague warranties, or poor customer service. Always compare specs, engineering standards, and what’s included in the quote before making a decision based on price alone.

5. How can I verify a metal building supplier’s credibility?

Look for certified engineering documents, clear warranty terms, and independent customer reviews. Reputable suppliers will be transparent about their process and happy to provide references, project photos, or case studies.