If you’re planning to put up a metal building, the structure is only as strong as what it sits on. Poor site preparation or a rushed foundation job can lead to costly repairs, project delays, and even structural failure. Unfortunately, many property owners and builders skip critical early steps, assuming they aren’t necessary when preparing a metal building foundation.

At Buildway, we’ve worked on hundreds of metal building projects across residential, agricultural, and commercial sectors. Time and again, we see the same problems arise: soft soils, drainage issues, misaligned anchor bolts, and unexpected permit complications. This guide brings together our field-proven insights to help you avoid these headaches and create a truly rock-solid foundation for your metal building.

Let’s break it down step by step.

Why Site Prep & Foundation Work Matters More Than You Think?

Every successful metal building starts with what’s beneath it. No matter how strong your steel frame is, it’s only as reliable as the ground it stands on. Proper site preparation and a well-built foundation protect your structure, your budget, and your timeline.

Skipping key steps here can lead to serious problems down the line, including:

- Settlement: When soil underneath shifts or compresses unevenly, it causes cracks in the floor or structure misalignment.

- Water damage: Improper grading and drainage can allow water to collect near your slab, leading to erosion or mold.

- Construction delays: Permit issues, utility line hits, or rework on misaligned bolt placements can slow your build to a crawl.

- Safety hazards: Sloping floors, cracked slabs, and loose structural connections all pose long-term safety risks.

Buildway Insight: We once had a project where the client had poured a slab without soil testing. Six months later, part of the slab settled nearly 2 inches, cracking a side wall and jamming doors. Fixing it cost more than the slab itself.

Proper prep prevents problems. In this guide, we’ll show you how to:

- Evaluate your soil

- Plan drainage and site layout

- Choose the right foundation

- Avoid common and costly mistakes

- Get permits and inspections right

Pre-Construction Checklist: What to Do Before You Break Ground

Before any equipment rolls in or concrete is poured, a few essential steps need to happen first. This early prep ensures your site is build-ready, compliant, and set up for long-term success.

Here’s what you need to take care of upfront:

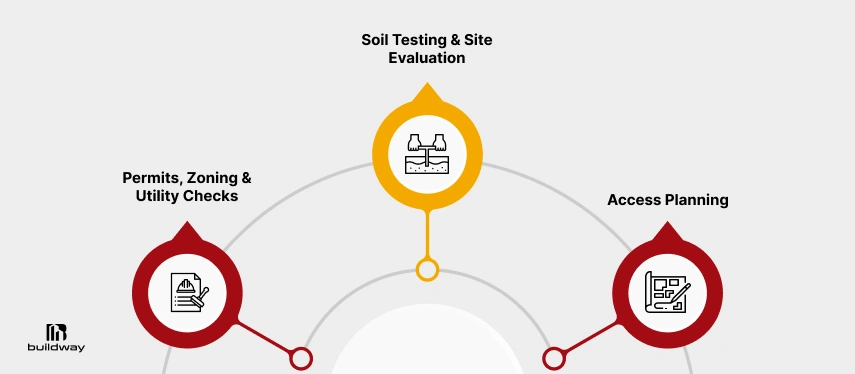

1. Permits, Zoning & Utility Checks

Before anything starts, confirm your project is legal and safe. Check with local authorities for the right permits, zoning rules, and underground utility locations.

- Building permits

- Zoning approvals (e.g. setbacks, land usage, height limits)

- Underground utility marking (gas, water, power lines)

Pro Tip: In many states, you can dial 811 to have underground utilities marked for free. Not doing this can lead to dangerous (and expensive) mistakes.

Buildway Experience: We’ve seen contractors halted mid-excavation because they hadn’t located underground sewer lines. This delayed the project by 2 weeks and cost the client $4,500 in fines and change orders.

2. Soil Testing & Site Evaluation

Before building, it’s essential to understand the soil beneath your foundation. Testing ensures the ground is stable, load-bearing, and suitable for long-term structural support.

Testing Includes:

- Soil classification (sand, clay, silt)

- Moisture content

- Bearing capacity (how much weight the soil can support)

This tells your engineer what type of foundation is needed and whether the soil needs improvement before building.

Why It Matters:

- Weak soil leads to slab cracks or sinking footings.

- Some soils (like clay) expand and contract with moisture, damaging slabs.

Buildway Insight: In rural areas, we often find organic topsoil that needs to be removed completely before building. Never pour concrete directly onto it. It doesn’t compact properly.

3. Access Planning

Before construction begins, it’s important to think through site logistics. Make sure there’s safe, clear access for equipment, material deliveries, and crew movement to avoid delays and damage during prep.

- Where will trucks unload?

- Can heavy equipment access the site without damaging prep work?

- Where will building materials be staged?

Pro Tip: Keep access routes separate from the main foundation area to prevent accidental soil disturbance after compaction.

Step-by-Step Site Preparation Process

Preparing your site is a detailed process that lays the groundwork for the strength, safety, and longevity of your metal building. Each step plays a vital role in making sure your foundation is stable, your drainage is effective, and your structure goes up without costly delays.

Here’s how to do it right, step by step.

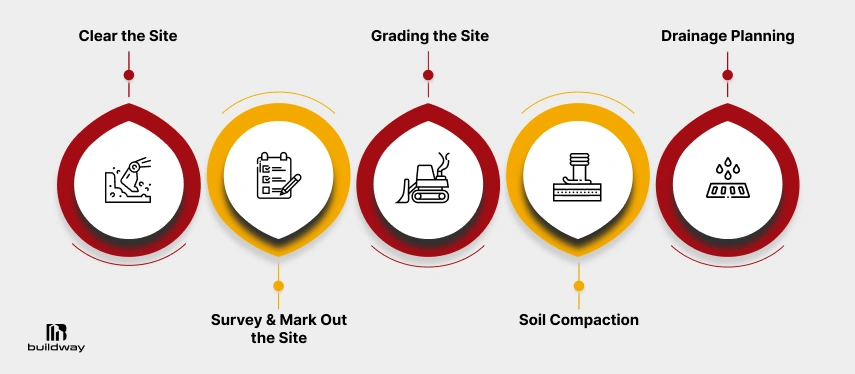

Step 1: Clear the Site

Once your plans are approved and permits are in place, the first step on the ground is clearing the site. This prepares the area for grading and ensures there’s nothing that could compromise your foundation later.

Here’s what needs to happen:

- Remove trees, brush, rocks, stumps, and any debris.

- Strip away topsoil. It’s too soft for building on.

- Excavate to the required depth, based on your engineer’s plan.

Depth Tip: Excavation usually goes 6–12 inches below grade, depending on frost line and drainage needs.

Step 2: Survey & Mark Out the Site

Before building, accurate layout is essential. Use proper survey tools to mark your foundation lines, corners, and anchor points to avoid alignment issues later.

Use professional survey equipment to:

- Establish exact building corners and centerlines

- Mark key locations for anchor bolts and foundation lines

- Confirm that the site is level and square

Why Precision Matters: Even a 1–2 inch misalignment can make steel framing difficult to fit, causing delays and costly rework.

Step 3: Grading the Site

Proper grading is key to keeping water away from your foundation. It shapes the site to control runoff and protect your slab from erosion and moisture damage.

- Grade the site with a minimum slope of 5% away from the foundation

- Create swales or gentle berms for water redirection

- Use compactable fill where needed to reach desired levels

Buildway Tip: Don’t over-rely on low-quality fill like sand or loose clay. Use engineered fill or crushed stone for durability and drainage.

Step 4: Soil Compaction

After grading, it’s critical to compact the soil properly. This step ensures your foundation sits on stable, load-bearing ground, and helps prevent settling or cracking later on.

Compaction Process:

- Use vibratory rollers or plate compactors

- Test compaction using a Proctor Test to ensure 95% density

| Soil Type | Compaction Tool | Target Density |

| Sandy | Vibratory plate/roller | 95–98% |

| Clay-rich | Sheepsfoot roller | Moisture-controlled |

Why This Matters: If your soil isn’t properly compacted, it can settle under your slab, causing cracks and uneven floors.

Real-World Example: A DIY client didn’t compact fill under a 40×60 workshop. The slab settled ¾ inch in one corner within 4 months, causing door misalignment and frame shifting.

Step 5: Drainage Planning

Water is one of your biggest enemies in construction.

Must-Have Drainage Features:

- Sloped terrain away from the building

- Perimeter gravel trenches to absorb runoff

- French drains or culverts where needed

- Downspout management and splash blocks

Buildway Tip: Install a 4–6-inch gravel border around your foundation perimeter to reduce splash-back and erosion. Simple, cheap, and effective.

Foundation Basics for Metal Buildings

Metal buildings demand accurate foundation work, especially when it comes to slab thickness and anchor bolt placement. Even small missteps here can cause costly delays during steel erection.

Common Foundation Types

| Type | Best For | Advantages |

| Isolated Footings | Small sheds, barns | Low-cost, minimal excavation |

| Monolithic Slab | Garages, workshops | Quick pour, clean finish |

| Raft or Mat Slab | Large commercial PEMBs | High strength, uniform support |

| Pier or Pile System | Poor soil or sloped sites | Deep stability, no surface slab |

Your engineer will recommend the best one based on soil strength, load requirements, and budget.

Anchor Bolt Placement

Anchor bolts are what connect your steel frame to the foundation, and they need to be spot-on. Even a small misalignment can delay steel erection and require costly fixes.

Key Considerations:

- Use shop drawing templates from the steel manufacturer

- Set bolts in concrete using anchor bolt jigs

- Check alignment before and after the pour

Buildway Insight: Improper bolt layout is the #1 cause of steel erection delays we encounter. Measure twice, pour once.

Curing & Inspection

Don’t jump ahead after the pour. Concrete needs time to cure and must pass key inspections before building can begin.

- Initial cure: 1–2 days

- Full strength: 14–21 days

- Inspection: Engineer checks bolt alignment, slab thickness, rebar, and finish quality

Pro Tip: Keep concrete moist during curing by covering with plastic or spraying water daily. Prevents cracking and ensures full strength.

What DIYers & Builders Often Get Wrong

Even experienced builders can overlook critical steps during site prep and foundation work. These are the most common mistakes we see at Buildway, and they’re often the ones that lead to delays, structural issues, or unexpected costs.

- Skipping Soil Tests: Trying to save $800 could cost you $8,000 in slab repairs.

- Poor Soil Compaction: You only get one chance before the slab is poured. Don’t eyeball it, use test equipment.

- Permit & Red Tape Delays: We’ve seen metal building kits arrive before permits are approved. This results in storage fees and frustrated crews.

Final Checklist Before You Pour Concrete

Before the concrete goes in, take a moment to double-check the essentials. This final checklist ensures your site is fully prepared, inspected, and ready for a successful foundation pour.

Pre-Pour Essentials:

- Soil tested and approved by an engineer

- Underground utilities marked (811 or local service)

- Site graded and compacted to required specs

- Drainage features (swales, gravel borders) installed

- Anchor bolts set and verified with shop drawings

- Engineer-reviewed layout and foundation plans

- All permits approved and on file

Download the Printable Site Prep Checklist.

Strong Foundations = Strong Buildings

Good site prep is the backbone of your entire project. At Buildway, we help builders, landowners, and contractors set themselves up for success before the first steel beam goes up.

Whether you’re building a barn, warehouse, or workshop, take the time to get the ground right. You’ll save thousands and build better.

Next Up: Metal Building Design Trends 2026. What You Need to Know.

Visual Notes for Designers

- Site grading diagram

- Anchor bolt layout template

- Compaction equipment photos

- Comparison table: soil types vs foundation types

FAQs About Metal Building Foundations

1. How deep should excavation go for a metal building foundation?

Excavation typically goes 6 to 12 inches below the finished grade, but this depends on your local frost line, drainage plan, and foundation type. In colder climates, you may need to dig deeper to prevent frost heave. Always refer to your engineer’s recommendations based on soil conditions and load requirements.

2. Do I need a concrete slab for a metal building?

In most cases, yes. A concrete slab provides a stable, level base for anchoring steel columns and supports. It also resists shifting, improves drainage, and increases the overall lifespan of the structure. For small, temporary, or non-load-bearing buildings, gravel or pier foundations may be acceptable, but rarely recommended.

3. Can I prepare the site for a metal building myself?

You can handle basic clearing and layout on small, simple projects. However, for most metal buildings—especially commercial or structural applications—professional site prep is highly recommended. Critical tasks like soil testing, grading, compaction, and drainage planning require specialized knowledge and equipment to meet building code and ensure long-term durability.

4. How long does metal building site preparation take?

Site prep typically takes 1 to 2 weeks, depending on:

- Soil condition

- Weather delays

- Site accessibility

- Foundation type

Larger or more complex projects (e.g., sloped land or poor soil) may take longer, especially if additional grading, fill, or drainage work is needed.

5. Are inspections required before pouring concrete?

Yes. Most local jurisdictions require several inspections during the pre-pour phase, including:

- Soil compaction certification

- Rebar placement check

- Anchor bolt layout inspection

- Formwork and elevation check

Some areas also require engineer sign-off before the concrete is poured.

6. What type of soil is best for metal building foundations?

The best soil is well-drained, compactable soil such as granular soil, gravel, or sand with minimal clay. These types offer excellent load-bearing capacity and low moisture retention. Clay-heavy or organic soils (like topsoil) often need to be removed or stabilized with engineered fill.

7. Can poor site prep affect my metal building warranty?

Absolutely. Most PEMB (Pre-Engineered Metal Building) manufacturers require a properly prepared and engineered foundation for warranty coverage. If your slab cracks, settles, or shifts due to improper soil prep or compaction, the warranty could be voided—leaving you responsible for costly repairs.

8. Do I need to install drainage around my metal building?

Yes. Proper drainage is essential to prevent water from pooling near your foundation, which can cause erosion, slab cracking, and long-term structural issues. Drainage solutions include:

- Sloped grading

- Perimeter gravel trenches

- French drains or swales

- Gutters and downspout extensions

9. What is a Proctor test and do I need one?

A Proctor test measures the maximum density of compacted soil and determines how well it will support your structure. It ensures your soil reaches at least 95% compaction (standard requirement for building foundations). Yes, this test is highly recommended and often required by code or engineers before pouring the slab.

10. When can I start erecting the building after the concrete is poured?

You can typically begin erection 14 to 21 days after the pour, once the concrete has cured to the required strength (usually around 3,000 psi). Your engineer or inspector should confirm this before proceeding. Rushing this step can cause anchor bolt shifting and slab damage.