When planning a warehouse, hangar, or large-scale industrial building, one of the most important choices you’ll make is the structural frame. Among the most trusted options are I-Beam steel buildings: known for their strength, durability, and ability to span large distances without interior support.

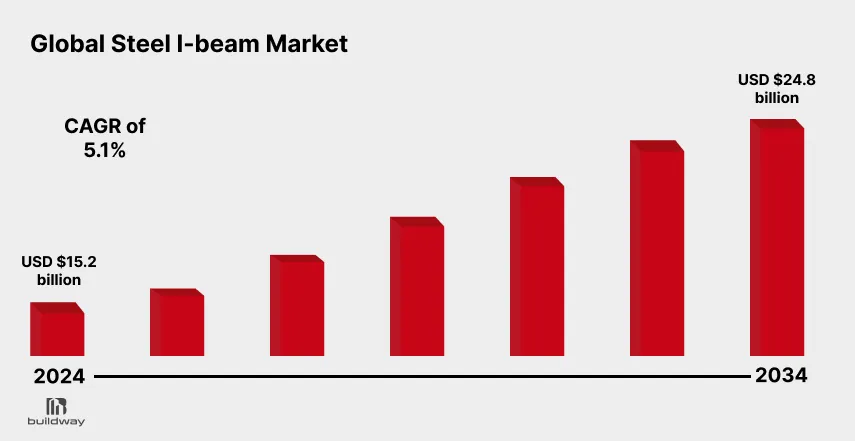

Reflecting this demand, the global steel I-beam market was valued at USD 15.2 billion in 2024 and is expected to reach USD 24.8 billion by 2034, growing at a CAGR of 5.1%. This growth highlights their expanding use across industrial, commercial, and agricultural sectors.

In this blog, we’ll break down how I-beam buildings work, where they shine, and whether they’re the right fit for your project.

What Are I-Beam Steel Buildings?

An I-beam steel building is a prefabricated structure built with welded steel I-beams shaped like the letter “I”, that form the vertical columns and horizontal rafters. These components are the core of the rigid-frame system, designed to support heavy loads, large clear spans, and demanding industrial conditions.

I-beam buildings are engineered and fabricated off-site and then assembled on-site with bolted or welded connections, offering a blend of structural strength, design flexibility, and fast construction timelines.

Key Components of an I-Beam Building:

An I-beam steel building is a precisely engineered system where each component plays a critical role in structural integrity and performance. Here’s a quick breakdown of the core elements that make up a typical I-beam building:

- Columns: Vertical members transferring loads to the foundation.

- Rafters: Sloped beams forming the roof frame.

- Moment Connections: Bolted or welded joints that create a fixed connection between columns and rafters, allowing the entire frame to resist bending and lateral forces.

- Purlins & Girts: Secondary framing members supporting roof and wall panels.

What Makes an I-Beam Different from Other Steel Members?

The “I” shape of the beam isn’t just for looks. It’s the result of engineering optimization. I-beams are designed to carry the highest amount of load with the least amount of material, making them strong, efficient, and cost-effective over the building’s lifetime.

I-Beams Offer:

- Superior Bending Resistance: The flanges handle compression and tension; the web resists shear forces.

- Efficient Load Transfer: I-beams direct forces down through columns to the foundation with minimal deflection.

- Material Efficiency: Less steel is needed compared to solid rectangular beams for the same strength output.

- Custom Sizing: I-beams can be fabricated to meet specific load and span requirements.

In short, I-beams give you more strength per dollar spent on steel than other framing options.

How Rigid-Frame Steel Buildings Work

The rigid frame is the structural skeleton of the building. Unlike post-frame or light-gauge buildings, which rely on flexible joints or diagonal bracing, rigid frames use fixed (moment) connections that behave as a unified structure. This allows the building to carry vertical, horizontal, and torsional (twisting) loads simultaneously.

Key Design Concepts:

- Moment Connections: These are the backbone of the rigid-frame system. They resist rotation at joints, allowing the structure to support significant lateral loads from wind and seismic activity.

- Load Paths: Loads from the roof (including snow, equipment, and dead weight) are transferred through rafters → columns → foundation.

- No Interior Columns (Clear Span): By using deeper or thicker I-beams, designers can eliminate internal supports altogether, maximizing usable floor space.

Clear Span Design Explained

A clear span design removes interior columns, creating wide, open spaces that improve flexibility and workflow. With rigid-frame I-beam construction, these buildings support heavy roof loads while keeping the entire floor area fully usable. Ideal for operations that need unobstructed space.

Clear-span I-beam buildings are especially well-suited for:

- Warehouse racking and forklift movement

- Overhead crane and lifting systems

- Indoor sports and recreation facilities

- Aircraft hangars and aviation maintenance

Depending on factors such as building height, roof pitch, and local wind or snow loads, I-beam clear spans can exceed 200 feet, making them one of the most effective solutions for large-scale, open-layout structures.

Strength Advantages of I-Beam Construction

Strength is the primary reason buyers choose I-beam steel buildings. Engineered to withstand substantial vertical and lateral forces, these structures are built to perform reliably in demanding conditions, including high winds, heavy snow loads, and seismic environments.

How I-Beams Handle Heavy Loads

- Section Modulus: This key engineering metric determines bending capacity. I-beams have a high section modulus, meaning they can span longer distances under heavier loads with less deflection.

- Wind & Seismic Resistance: The rigid-frame design efficiently distributes lateral loads through the frame instead of relying on external bracing or shear walls.

- Snow Loads: The steep roof pitches and heavy-duty rafters of I-beam buildings are excellent for areas with significant snow accumulation.

In coastal, snowy, or earthquake-prone regions, rigid-frame I-beam systems are often a requirement to meet building codes.

Looking for a Steel Building Right Now? Explore our latest clearance steel building deals. Ideal for buyers needing fast, cost-effective solutions without compromising on strength or code compliance.

Need something custom-built? Contact us or request a quote and let our experts help you choose the right I-beam frame for your project, timeline, and location.

Typical Building Sizes & Span Ranges

I-beam steel buildings are fully customizable, with spans, lengths, and heights designed to match specific operational needs and site conditions. The guide below outlines typical span ranges to help you plan effectively:

| Span Width | Ideal For |

| 30’–60′ | Small warehouses, farm shops, automotive bays |

| 60’–100′ | Manufacturing plants, logistics hubs |

| 100’–200’+ | Aircraft hangars, arenas, mega-storage |

Beyond 100’, I-beam buildings become the only economical choice for structures needing wide-open space. Their rigidity also enables taller sidewalls (30’+), ideal for vertical storage or large machinery clearance.

Industrial & Commercial Use Cases

Rigid-frame I-beam buildings are a preferred choice across industries that demand durability, efficient use of space, and reliable performance under heavy stress. Their structural strength and adaptability make them ideal for high-demand commercial, industrial, and agricultural applications.

Common Applications:

- Warehouses: Fast assembly, scalable bays, racking compatibility.

- Manufacturing Facilities: Support for cranes, heavy equipment, mezzanines.

- Aircraft Hangars: Long clear spans, tail-height clearance, wind resistance.

- Agriculture: Grain storage, hay barns, riding arenas, equipment housing.

- Energy/Utilities: Power plants, recycling centers, substations.

Why These Industries Choose I-Beam Systems

Industries with demanding operational needs turn to I-beam steel buildings because of their unmatched strength, efficiency, and long-term value. From manufacturing plants to aviation hangars, these structures offer benefits that go far beyond basic shelter.

- I-beam buildings offer a long service life with minimal maintenance, even in harsh environments.

- They provide excellent value per square foot over time, thanks to their durability and structural efficiency.

- The rigid frame can easily support large overhead doors, cranes, and heavy HVAC systems.

- The clear-span design allows for flexible interior layouts without the need for interior columns.

- These buildings meet or exceed local building codes for wind, snow, and seismic loads, ensuring compliance and safety.

For industries that require strength, flexibility, and reliability, I-beam systems deliver a proven, long-term solution.

I-Beam vs Other Steel Building Systems

Choosing the right steel framing system starts with understanding how each option compares. I-beam steel buildings differ significantly from tube steel and cold-formed systems in terms of strength, span capacity, cost, and use cases. The comparison below highlights the key differences to help you make a more informed decision.

| Feature | I-Beam Steel | Quonset Steel | Cold-Formed Steel |

| Max Clear Span | 200’+ | ~80′ | ~50′ |

| Structural Strength | High | High | Low–Moderate |

| Ideal Use | Industrial, Commercial | Agricultural, Workshops, Storage | Residential, Light Use |

| Assembly Complexity | Requires lift equipment | Easy, can be DIY | Easy, DIY possible |

| Longevity | 50+ years | 40–60 years | 15–25 years |

| Cost Efficiency | Higher upfront, lower long-term | High (low material & labor costs) | Lowest upfront |

I-beam systems are best suited for scalable, heavy-duty applications, but they’re not the right fit for DIY or small residential projects.

For a more in-depth breakdown of framing types, check out our full guide: Cold-Formed vs I-Beam vs Quonset – Which Steel Building is Best for You?

Is an I-Beam Steel Building Right for You?

Choosing the right steel building system depends on a combination of factors like project size, structural needs, site conditions, budget, and long-term goals. I-beam steel buildings offer significant advantages, but they aren’t the right solution for every project. Here’s a breakdown to help you evaluate if they’re the right fit for you:

When to Choose an I-Beam Building

An I-beam steel building is likely the best option if your project requires:

- Clear spans over 60 feet for unobstructed interior space

- Support for heavy equipment or overhead cranes

- High structural performance in areas with wind, snow, or seismic loads

- Tall sidewalls or overhead doors for machinery access or storage needs

- Long-term durability with minimal maintenance over decades of use

- Future expansion capability, thanks to the modular frame design

When to Consider Alternatives

I-beam systems may not be the best choice in situations such as:

- Projects involving small-scale or residential structures like garages or sheds

- Tight budgets that prioritize short-term, low-cost construction

- Remote or DIY job sites where crane access or skilled labor for welding/bolting is limited

Understanding your project’s scale and structural demands is key to selecting the most efficient and cost-effective system. For larger, more demanding builds, I-beam frames often provide unmatched long-term value.

Once you’ve selected the right frame, proper site prep becomes critical. Don’t miss this guide on everything you need to do before your steel building kit arrives to avoid costly delays and ensure a smooth build.

Conclusion

I-beam frames are just one part of a complete engineered steel building system. From cladding and insulation to doors, accessories, and site preparation, our team helps you create a fully integrated, code-compliant building tailored to your operations.

We also offer free design consultations and a downloadable Steel Building Structural Guide (PDF) to help you compare options.

Explore Our Steel Building Systems or Compare Steel Building Types: Cold-Formed vs I-Beam vs Quonset to find the best fit for your project.

FAQs

1. How far can an I-beam steel building span without interior columns?

I-beam steel buildings can achieve clear spans of up to 200 feet or more, depending on the building’s height, local load requirements, and overall structural design. This makes them ideal for applications needing wide, open interior space without columns.

2. Are I-beam buildings suitable for snowy or high-wind areas?

Yes, I-beam buildings are engineered to meet or exceed local snow, wind, and seismic load codes. Their rigid-frame design offers excellent resistance to extreme weather, making them ideal for regions with harsh environmental conditions.

3. Can an I-beam building support an overhead crane system?

Absolutely. I-beam buildings can be custom-engineered to support bridge cranes, monorails, jib cranes, and gantry systems. This is a common feature in manufacturing, logistics, and heavy-equipment facilities.

4. Is it easy to expand an I-beam steel building in the future?

Yes. I-beam buildings are designed for modular expansion, allowing you to add bays or increase the length with minimal disruption. This makes them a flexible solution for growing operations.

5. How long does it take to build an I-beam structure?

Typical timelines include 2–6 weeks for manufacturing and delivery, and 2–12 weeks for erection, depending on the size, complexity, and site conditions.

6. What is the lifespan of an I-beam steel building?

With proper maintenance, I-beam steel buildings can last 50 years or more. Their steel components are resistant to pests, rot, and fire, contributing to long-term structural performance.

7. Do I-beam buildings require special equipment to assemble?

Yes. Due to the size and weight of the I-beams, cranes or forklifts are typically required during erection. Skilled labor or professional installation is recommended.

8. Are I-beam steel buildings more expensive than other types?

I-beam buildings usually have a higher upfront cost compared to cold-formed or tube steel systems, but they offer greater strength, durability, and long-term value, especially for large or demanding structures.

9. Can I customize the roof pitch or sidewall height of an I-beam building?

Yes. I-beam buildings offer complete design flexibility, including custom roof pitches, tall sidewalls, variable bay spacing, and tailored load capacities to match your operational needs.