Steel buildings have come a long way from the drafty warehouses and sweltering metal sheds of the past. Yet, the stigma persists. For many, the phrase “metal building” conjures images of unbearable summer heat, poor insulation, and sky-high HVAC costs.

But the truth is: energy efficient steel buildings can be designed to outperform traditional structures in thermal performance, air tightness, and lifecycle sustainability.

In this comprehensive guide, we’ll break down:

- Why the “heat trap” myth still exists

- How heat actually moves in a steel building (and how to stop it)

- Cutting-edge insulation and roofing systems

- Real-world data from government and lab studies

- Tips for designing energy-efficient steel buildings

- FAQs backed by science, not assumptions

Let’s separate outdated myths from modern building science.

The Core Misconception: “Steel Buildings Trap Heat”

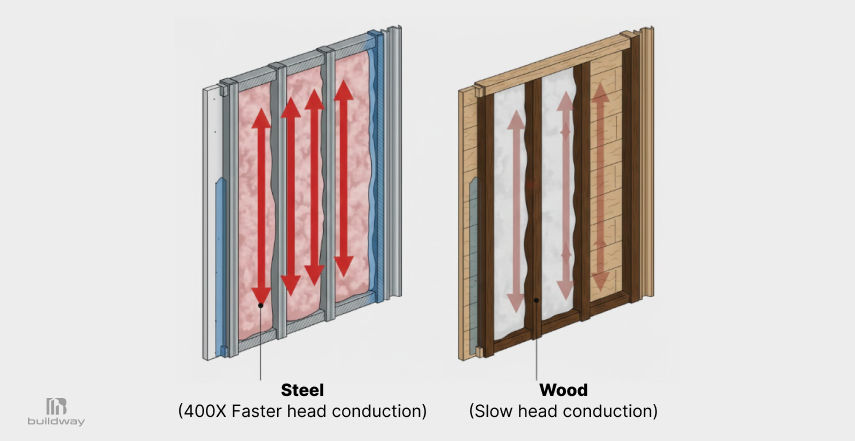

Steel has a high thermal conductivity, which means it transfers heat more easily than materials like wood. However, conductivity is not the same as inefficiency. And yet, many still believe metal buildings are naturally hot in summer and freezing in winter.

Why Steel Gets Blamed for Energy Loss

- Legacy buildings without insulation: Many older metal structures (barns, workshops, sheds) were built with no insulation or vapor control, leading to real performance issues. But these were never designed to be efficient in the first place.

- Confusion around conductivity: Steel does conduct heat, but the way heat moves through a building depends on many factors like roof reflectivity, insulation strategy, air tightness and not just the frame material.

- Visual bias: Metal buildings often look industrial or “cold,” leading to subconscious assumptions about their interior performance.

Conductivity vs. Whole-Building Performance

While steel conducts heat more than wood, thermal conductivity alone doesn’t determine a building’s energy efficiency. What truly matters is the performance of the entire building envelope including insulation, air sealing, and roof reflectivity.

Energy-efficient steel buildings that follow current energy codes can match or even outperform wood-framed buildings when designed as a system.

Key Takeaways:

- Efficiency depends on the whole system: roof, walls, insulation, and airtightness, not just the structural material.

- Thermal bridging in steel can be mitigated with rigid insulation, thermal breaks, and spray foam.

- Steel structures often allow better airtightness, thanks to panelized construction with fewer joints.

- Insulated steel buildings can exceed code requirements with R-30+ roof systems and R-19+ wall assemblies.

- Properly designed steel buildings can outperform wood in hot and cold climates when insulation and roofing systems are optimized.

Steel isn’t the problem, poor design is. When done right, steel is not just a viable option but a high-performance solution.

Why Energy Efficient Steel Buildings Outperform Traditional Construction?

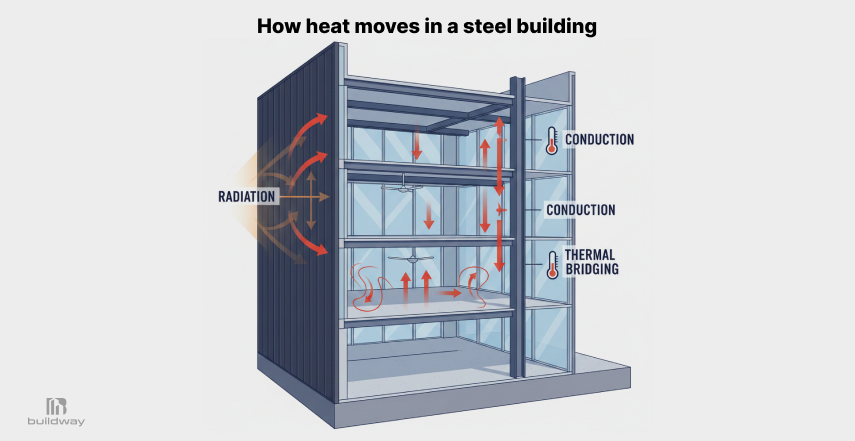

To understand why steel buildings can be efficient, it helps to understand the three primary modes of heat transfer: radiation, conduction, and convection.

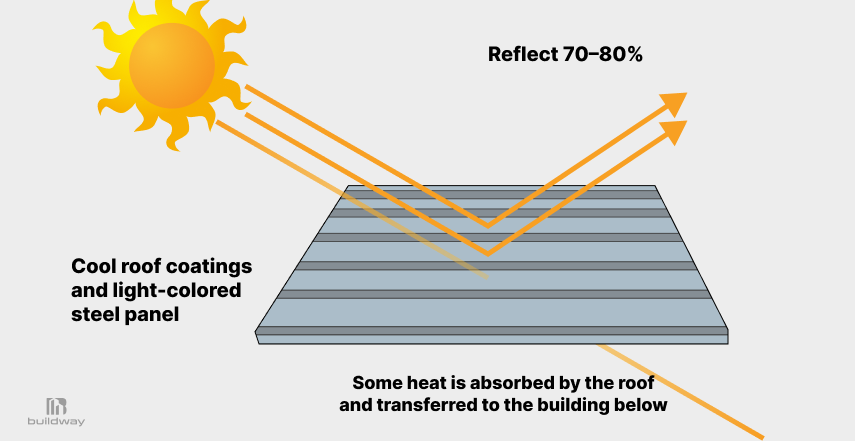

1. Radiation: Solar Gain on Roofs: When sunlight hits your roof, energy is absorbed or reflected. Traditional dark metal panels can absorb large amounts of solar heat, raising roof temps by up to 150°F on a hot day.

Modern solution: Cool roof coatings and light-colored steel panels reflect 70–80% of solar radiation, significantly reducing surface temperature and indoor heat gain.

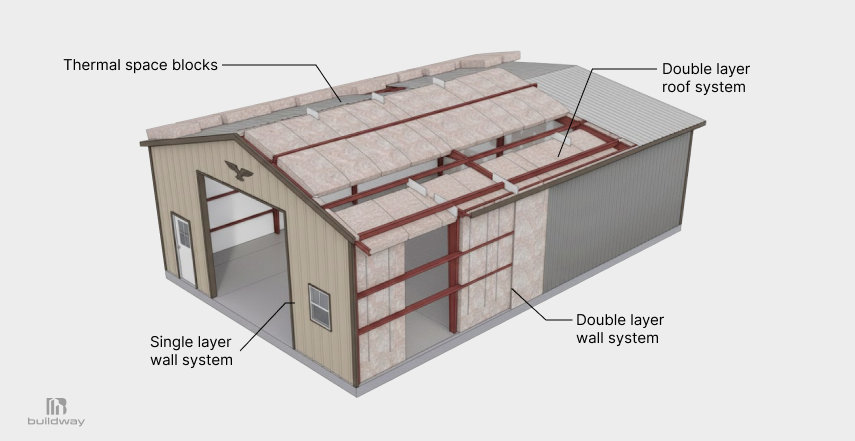

2. Conduction: Thermal Bridging Explained: Conduction happens when heat travels through materials like steel framing into the building. Steel conducts heat 400 times faster than wood, which is why “thermal bridging” is a concern.

Prevention methods:

- Continuous rigid insulation

- Thermal spacer blocks

- Spray foam around joints and penetrations

These strategies break the thermal bridge and create a more stable, insulated envelope.

3. Convection: Air Leakage & Airtightness: Air leaks are silent energy killers. Warm air escapes in winter, and hot air sneaks in during summer, forcing HVAC systems to work harder.

Steel advantage: With panelized construction, steel buildings have fewer seams and joints than stick-built ones. This means less air leakage, better pressure control, and improved comfort.

Cool Roof Steel: The Most Overlooked Energy Advantage

One of the biggest yet least discussed benefits of energy efficient steel buildings is the adoption of cool roof technology. By reflecting solar heat instead of absorbing it, cool roof steel panels significantly reduce interior heat gain and cooling demand, making them one of the most effective upgrades for improving energy performance.

What Is a Cool Roof Steel Panel?

Cool roofs are metal panels coated with solar-reflective pigments that reduce heat absorption. They reflect solar energy back into the sky, helping lower rooftop and interior temperatures.

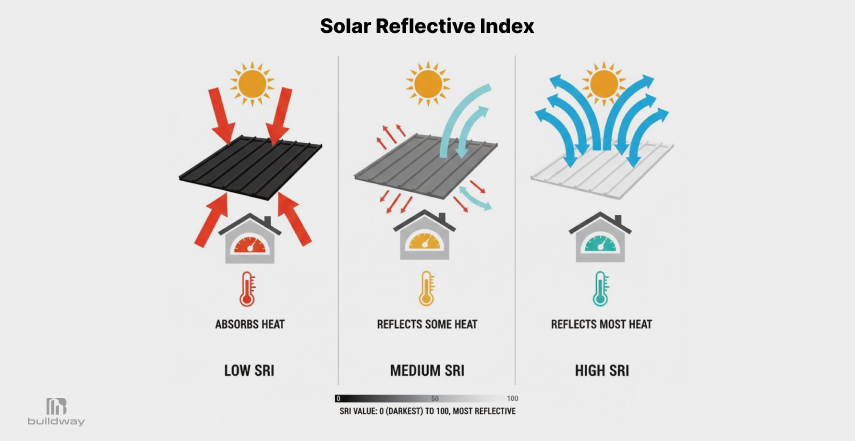

Understanding SRI: Solar Reflectance Index

- SRI measures how well a roof reflects solar heat and emits absorbed heat.

- Panels with SRI 70+ are considered high-performing.

- Reflective steel panels can reduce rooftop temps by 50–60°F.

Fun Fact: For every 1°F drop in roof temperature, you can see up to 1.5% savings on cooling costs.

What the Data Shows (DOE & Oak Ridge Studies)

- DOE studies found that cool metal roofs can lower indoor temperatures by 5–10°F.

- Cooling energy savings range from 7% to 15% annually, depending on climate and insulation strategy.

Advanced Insulation Systems for Steel Buildings

Insulation is key to the high performance of energy efficient steel buildings, helping eliminate the outdated “heat sink” issue. Today, builders can choose from a wide range of systems that ensure steel buildings retain or repel heat effectively.

1. Continuous Rigid Insulation: Applied outside the frame, this system provides an uninterrupted thermal barrier and helps eliminate bridging.

2. Fiberglass with Thermal Blocks: Fiberglass batt systems paired with thermal spacers or blocks help prevent cold transfer through steel members.

3. Spray Foam & Hybrid Systems: Closed-cell spray foam provides:

- High R-values (R-6 to R-7 per inch)

- Vapor and air barriers

- Seamless coverage around penetrations

When combined with batt or rigid board insulation, it creates a hybrid envelope that excels in all climates.

How Energy-Efficient Steel Buildings Achieve Code Compliance?

Modern steel buildings when properly insulated can achieve impressive thermal performance that meets or exceeds most energy codes across the U.S. With the right combination of materials and installation, steel structures can easily rival traditional buildings in insulation efficiency.

Typical R-Values for Well-Designed Steel Buildings:

- Roofs: R-30 to R-38

- Walls: R-19 to R-25

These values provide excellent thermal resistance, reduce heating and cooling loads, and help maintain comfortable indoor conditions year-round.

Airtightness: The Silent Performance Hero of Steel Construction

Airtightness is one of the most underrated factors in building performance, yet it plays a major role in real-world energy savings. Even the best insulation won’t perform as expected if air is leaking through gaps and seams.

Fewer Gaps, Better Control: Steel buildings are built from large panels with tight factory tolerances, meaning fewer opportunities for air leakage.

Steel vs. Wood: Air Leakage Tests

When it comes to airtightness, steel buildings have a measurable edge. Blower door tests used to assess air infiltration consistently show that well-designed steel structures perform better than their wood-framed counterparts.

Key Findings from Air Leakage Testing:

- 30–50% lower air infiltration in steel buildings with panelized construction

- Fewer seams and tighter joints reduce unintended air exchange

- Less air leakage = less energy lost, leading to lower heating and cooling demands

This reduced infiltration not only improves comfort but also contributes to long-term energy savings.

Green Metal Buildings & Long-Term Energy Benefits

Sustainability is about how a building holds up over time. Energy-efficient steel buildings excel in long-term performance, thanks to their material stability and low degradation.

Recycled Steel & Embodied Carbon

- Steel is the most recycled construction material in the world.

- Many buildings use up to 90% recycled steel, significantly reducing embodied carbon.

Longevity, Durability, and Insulation Stability

- Steel doesn’t degrade like wood.

- Panels and insulation systems retain integrity over time, which means:

- No R-value loss

- No warping

- Less maintenance

The result? Buildings that perform just as well in year 30 as they did on day one.

What the Data Actually Says (Summary Table)

| Performance Factor | Modern Steel Building | Traditional Wood Frame |

| Roof Reflectivity | High (SRI 70+) | Low to Medium (SRI <35) |

| Insulation (R-Value) | R-19 to R-38+ | R-13 to R-21 |

| Air Leakage | Low (tight seams, few joints) | Medium–High (many seams) |

| Lifecycle Efficiency | Very High | Moderate (wood degrades) |

| Embodied Carbon | Low (recycled steel) | High (new lumber) |

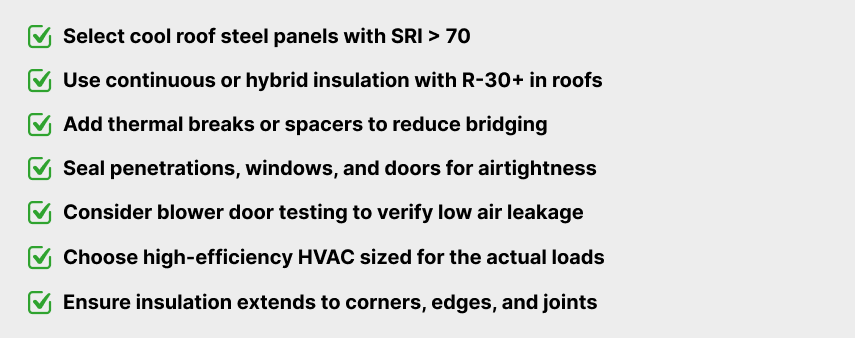

Practical Energy Tips for Steel Building Owners

You don’t need a PhD in building science to make smart energy decisions. Here’s a simple checklist to maximize performance:

Conclusion

Today’s energy efficient steel buildings, designed with reflective roofing, smart insulation, and airtight construction, can be among the most sustainable structures on the market.

Want to Save on Energy Costs? Download the Energy-Efficient Steel Building Design Checklist or Contact Us Today. Optimize your roof, walls, and insulation for better comfort and lower bills.

FAQs: About Energy-Efficient Steel Buildings

1. Are steel buildings energy efficient?

Yes, steel buildings can be highly energy efficient when designed with modern insulation, cool roofing, and airtight construction. With the right building envelope strategy, they can match or exceed the performance of traditional wood-framed structures.

2. Do metal buildings get hotter than wood buildings?

Not when properly designed. Steel buildings with cool roof panels and quality insulation often stay cooler than wood buildings, thanks to their reflective coatings and superior airtightness.

3. Does steel retain heat?

No, steel conducts heat but doesn’t retain it. With the use of continuous insulation, thermal breaks, and air sealing, steel buildings can maintain comfortable interior temperatures year-round without overheating or excessive heat loss.

4. What is the best insulation for steel buildings?

The most effective insulation approach is a hybrid system that combines:

- Spray foam (for air sealing and high R-value)

- Rigid board insulation (to prevent thermal bridging)

- Batt insulation (in cavity spaces)

This layered strategy works across all climate zones and building types.

5. Are steel buildings considered green or sustainable?

Yes. Steel is one of the most sustainable construction materials available. It’s:

- Up to 90% recycled

- Durable and long-lasting (low lifecycle emissions)

- Compatible with high-performance insulation and roofing systems

Steel buildings also maintain energy efficiency without degrading over time.

6. Do steel buildings meet energy codes?

Absolutely. Modern steel buildings can be designed to meet or exceed energy codes like:

- IECC (International Energy Conservation Code)

- ASHRAE 90.1

- Local state and municipal standards

They often outperform stick-built buildings in areas like airtightness and insulation continuity.

7. Can steel buildings be LEED certified?

Yes. Steel buildings can qualify for LEED certification (or other green building standards) by using:

- Recycled content

- Efficient HVAC systems

- High-performance insulation and air sealing

- Cool roofing materials

Many LEED points are available through energy optimization and material sourcing in steel construction.

8. How do you reduce energy loss in a steel building?

To minimize energy loss in steel buildings:

- Use cool roof steel panels with high solar reflectance

- Install continuous insulation to eliminate thermal bridging

- Apply air barriers and seal all joints to prevent leaks

- Include thermally broken connections at structural framing points.

These strategies work together to create a tight, efficient thermal envelope.

9. Do metal buildings lose heat faster in winter?

Not if insulated properly. With R-30+ roofing, R-19+ walls, and airtight construction, modern metal buildings can maintain warmth just as effectively or better than traditional buildings.

10. Are reflective metal roofs worth it?

Yes. Reflective metal roofs (cool roofs) can:

- Reflect up to 70–80% of solar radiation

- Lower roof surface temps by 50°F–60°F

- Cut cooling costs by up to 15% annually

This makes them one of the most cost-effective energy upgrades for steel buildings, especially in warmer climates.