Strong and Reliable Steel I Beam Structures That Provide Lasting Performance and Value

Steel I Beam Buildings

What is an I-Beam?

Build Stronger with Buildway’s Steel I Beam Buildings

Why I-Beam?

Steel I beams offer outstanding strength and design flexibility, carrying heavy loads while reducing material costs. Built to resist bending, weather, and wear, they’re a durable, low-maintenance choice for commercial, residential, industrial, and agricultural buildings, making them a smart, long-lasting investment. With adaptable sizes and precise manufacturing, they fit a wide range of projects.

Start your steel I Beam building project now.

We guide every client from consultation and design approval to in-house manufacturing and fast delivery. Transparent pricing and customization options support a smooth buying experience.

I-Beam Building Accessories

Each of our system is backed by the proven strength of Galvalume Plus™ steel, ensuring resilience, energy efficiency, and decades of dependable use. This guarantees that every accessory offers durable performance and supports the overall integrity of your steel I Beam building.

Colors

Design your perfect building with our wide range of color options. Customize every detail by selecting corner, eave, wall, gable, jamb, and roof colors.

Gutters & Downspouts

Our gutters and downspouts effectively channel rainwater away from your building, protecting its foundation and exterior from water damage.

Insulation

We provide premium heavy-duty blanket insulation with enhanced toughness. This insulation, made of densely packed fibers, is ideal for floors, ceilings, and wall interiors to improve energy efficiency and comfort.

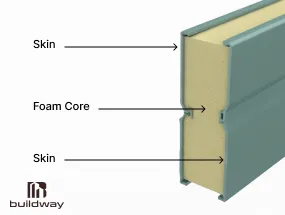

Insulated Metal Panels

Our insulated metal panels combine superior protection, design versatility, and fire resistance. They are suitable for a variety of architectural and performance needs.

Wall Liner Panels

Interior liner panels cover your building’s walls with durable steel sheeting. Typically 3-foot wide (29 gauge), these panels attach directly to framing and run from floor to roof, providing a clean, finished interior surface.

Prefab Foundation Systems

Our frost-resistant, floating slab foundations use high-strength steel to handle challenges like sensitive soils, frost heaving, water table issues, remote locations, and budget constraints.

Roof Jacks

Metal roof jacks mount securely on roof panels and accommodate stacks up to 12 inches, providing ventilation or exhaust options.

Service Door Frames

Choose from ready-made door frames sized for hangar, sliding, sectional overhead, or standard 4×7 service doors. Customize to fit your needs or install your preferred door with just the frame.

Soffit Panels

Our easy-install soffits offer design flexibility and long-lasting functionality, adding both form and durability to roof overhangs.

Translucent Light Transmitting Panels (LTPs)

Fiberglass reinforced panels allow natural light inside, reducing energy costs while brightening your space.

Univalent Roof Ventilators

These 26-gauge, 10-foot long gravity-type roof ventilators come in Polar White, with optional dampers, designed for continuous ventilation runs.

Window Frames

Bring natural light into your building with self-framing aluminum windows available with both thermal and non-thermal break options. These windows are designed to reduce lighting costs and enhance building aesthetics.

Have more questions?

FAQ’s

We’re here to help!

What are the limitations of I beam structures?

While very strong, I beams can twist if not properly braced. Slender sections may need stiffeners, and connections require careful engineering. For small spans, steel I beams may be more costly than light-gauge framing systems.

Do steel I beam buildings require interior columns?

Not always. One of the main advantages of steel I beam construction is the ability to create large, clear-span interiors with no interior supports. It’s perfect for storage buildings, manufacturing facilities, and aircraft hangars.

What types of buildings are best suited for steel I beams?

Steel I beams are best for structures needing wide spans and heavy load capacity, such as warehouses, industrial plants, factories, hangars, and large commercial buildings.

How is the size of an I beam determined?

The size of a steel I beam depends on span length, design loads (snow, wind, and live loads), and building code requirements. A structural engineer must determine the correct beam size using design tables and standards.

What foundation is required for steel I beam buildings?

Steel I beam columns are anchored to reinforced concrete footings or piers with base plates and anchor bolts. The foundation design depends on soil conditions and the loads being transferred.

Are steel I beam buildings expensive to erect?

Costs vary depending on steel prices, building size, and design complexity. For large spans and heavy loads, steel I beam framing is very cost-effective. For smaller buildings, lighter framing systems may be more economical.