In 2026, commercial metal buildings will continue to dominate the U.S. construction market for a simple reason: they offer the best balance between cost-efficiency, construction speed, and long-term flexibility.

Whether you’re planning a warehouse, manufacturing plant, retail facility, or storage space, understanding the true cost of commercial metal buildings can save you tens (or hundreds) of thousands of dollars.

Unfortunately, most price guides and builder quotes leave out critical details like foundation costs, labor fluctuations, permitting delays, and regional price spikes. This blog is written with real-world experience from builders, estimators working across the U.S. to give you honest, complete, and actionable information for your 2026 project.

What You’ll Learn in This Blog

- Actual 2026 commercial metal buildings cost per square foot

- A detailed breakdown of kit-only, installed, and turnkey pricing

- Real cost examples

- Key design decisions that increase or reduce cost

- Site prep, foundation, and labor cost realities

- Smart budgeting tips based on real builder insights

- When and how to lock in pricing in 2026’s inflationary environment

How Much Do Commercial Metal Buildings Cost in 2026?

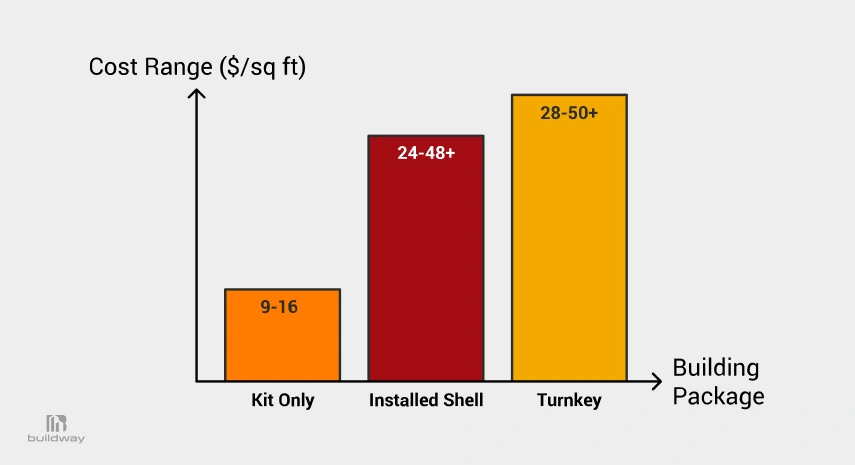

Let’s cut straight to the numbers. Commercial metal buildings also known as pre-engineered metal buildings or PEMBs come in three core pricing levels:

1. Kit Only

Includes: Steel frame, sheeting, doors, fasteners, blueprints

- Cost: $9 – $16/sq ft

- Best for: DIY-savvy builders or clients with local install teams

2. Installed Shell

Includes: Building kit + erection, insulation, basic weatherproofing

- Cost: $24 – $48+/sq ft

- Best for: Businesses with their own foundation contractor

3. Turnkey

Includes: Complete construction: kit, slab, installation, basic interior prep

- Cost: $28 – $50+/sq ft

- Best for: Those who want a full-service, no-hassle approach

Warning: Many online quotes are for kit-only pricing and do NOT include the slab, insulation, install labor, or interior systems. Always ask what’s included.

Real Cost Example: 100×100 ft Metal Building (10,000 sq ft)

Let’s take a typical 100’ x 100’ commercial metal buildings structure. Here’s what real buyers can expect to spend in 2026:

| Build Type | Estimated Cost Range |

| Kit Only | $90,000 – $160,000 |

| Installed Shell | $240,000 – $480,000 |

| Turnkey | $280,000 – $500,000+ |

Case Study: A user in Ohio shared that they were quoted $260K for a 10,000 sq ft steel building shell in late 2025. After factoring in site prep, permits, foundation challenges, and material upgrades, their total build cost reached $385K.

If you’re considering handling parts of the construction yourself to save money, check out our guide on DIY Metal Building Kits: How Much Can You Really Save? to understand the risks and true savings potential.

Important Pricing Clarification: Same-size buildings can have very different costs. Factors like wind loads, layout, door sizes, and site conditions all play a big role, so square foot pricing is just a starting point. Always get a custom quote based on your exact needs.

Now let’s understand this in detail.

Why Do Commercial Metal Building Prices Vary So Much in 2026?

While square footage gives you a starting point, the final cost of a commercial metal building depends on much more than size alone. A wide range of variables from engineering requirements to site conditions and regional labor rates, can significantly impact your total project cost.

Below, we break down the most important cost drivers to help you plan smarter and avoid budget surprises.

1. Steel Prices & Material Costs

As of Q1 2026:

- Hot-rolled coil (HRC) steel averages $830–$880 per ton.

- Prices are more stable than in 2022–2023, but still 20–25% higher than pre-2020 levels.

- Freight and fuel surcharges also affect delivered kit costs

Quote Validity: Most builders lock steel prices for 30–45 days. Delays beyond that may require repricing.

2. Design Complexity & Engineering Requirements

Beyond square footage, your building’s design has a major impact on cost. Structural choices, load requirements, and layout details can significantly change the amount of steel and the engineering needed to support it.

Key design features that increase cost:

| Feature | Added Cost Impact |

| Clear-span over 80’ | +$3–$7/sq ft (heavier beams) |

| Mezzanine floors | +$15–$35/sq ft |

| High snow or wind load areas | +$4–$12/sq ft |

| L-shaped or offset buildings | 10–15% more in steel & labor |

Pro Tip: Get engineered drawings early. Minor changes like an added door or column-free interior can swing prices dramatically.

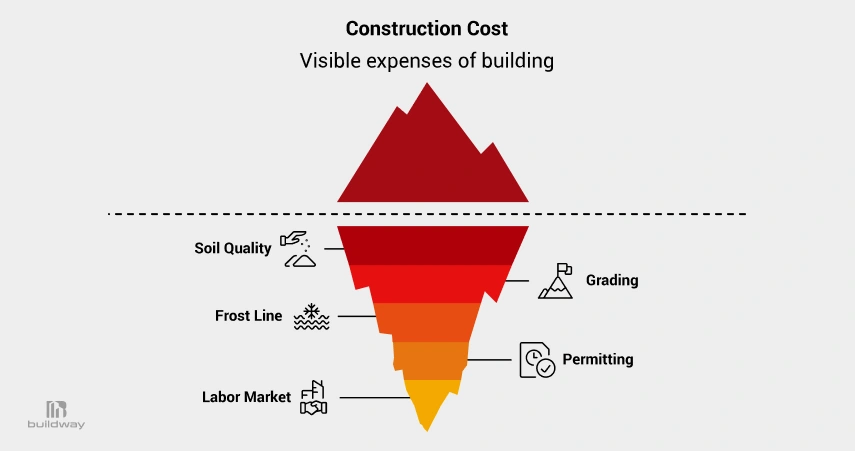

3. Site Location & Local Conditions

Where you build has a big impact on cost. From soil quality to permitting timelines, local factors can add unexpected expenses and in 2026, tight labor markets in many regions are making construction even more costly.

Factors affecting site cost:

- Soil quality: Poor soil may require deeper foundations

- Grading: Sloped lots can add $15,000 – $50,000+

- Frost line: Deeper footings in northern states increase concrete volume

- Permitting: Some jurisdictions take 4–6 months to issue approvals

In 2026, labor remains tight in many regions, pushing up installation and concrete costs, especially in the Southeast and Mountain West. Foundation and site prep issues can blow your budget fast. Here’s How to Get It Right.

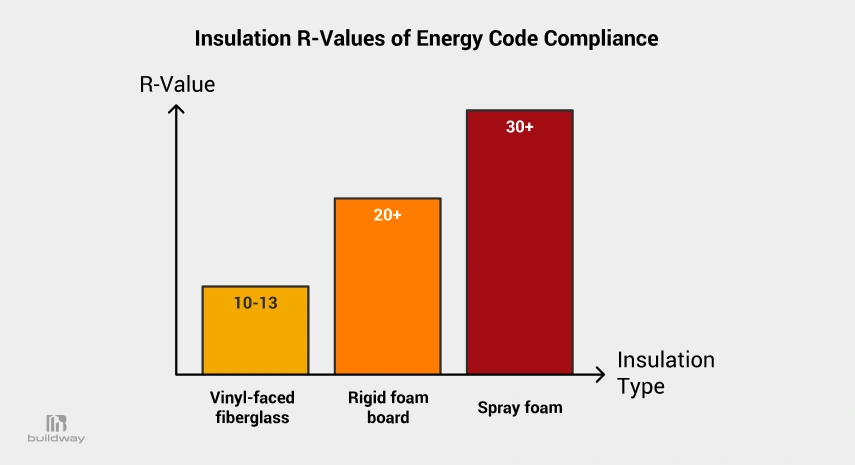

4. Insulation & Energy Code Compliance

In 2026, meeting updated IECC energy codes is no longer optional. Your choice of insulation directly affects compliance, energy efficiency, and total build cost, especially in colder regions.

| Insulation Type | R-Value | Notes |

| Vinyl-faced fiberglass | R-10 – R-13 | Budget-friendly, minimal compliance |

| Rigid foam board | R-20+ | Common in commercial/retail use |

| Spray foam | R-30+ | High upfront cost, best efficiency |

Buildings in cold or mixed climates will likely require at least R-19 roof and R-13 walls to meet code.

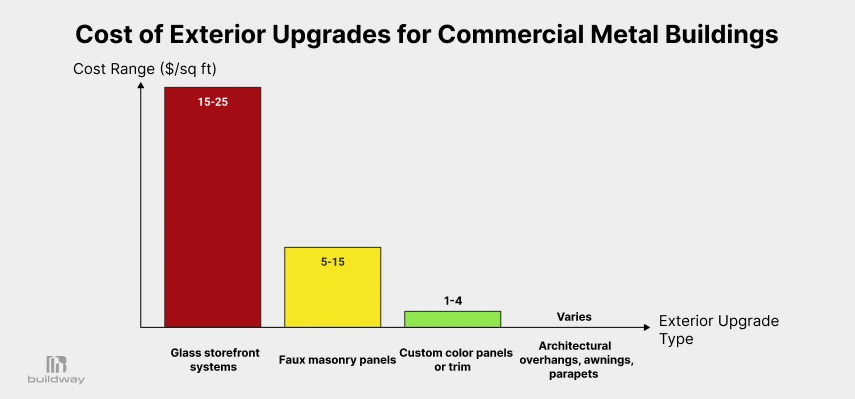

5. Exterior Upgrades & Custom Finishes

A basic metal shell gets the job done, but if your building needs curb appeal, those aesthetic upgrades can add up fast. From glass storefronts to custom trim, design choices impact both cost and first impressions.

- Glass storefront systems: +$15–$25/sq ft

- Faux masonry panels: +$5–$15/sq ft

- Custom color panels or trim: +$1–$4/sq ft

- Architectural overhangs, awnings, parapets: Varies by project

Aesthetics matter especially for retail, medical, or office spaces. But they come at a price.

Are Metal Buildings Still the Most Cost-Effective in 2026?

Yes, when comparing structural systems, metal buildings continue to offer the best value in 2026. Thanks to faster build times, lower material costs, and long-term flexibility, PEMBs remain the most cost-effective choice for many commercial applications. Here’s why:

| Build Type | Avg. Cost per Sq Ft (2026) | Avg. Build Time | Flexibility |

| Metal / PEMB | $28 – $50+ | 12–20 weeks | High |

| Wood Frame | $50 – $100+ | 20–30 weeks | Moderate |

| Concrete / CMU | $60 – $125+ | 18–26 weeks | Low |

When it comes to speed, structural efficiency, and future scalability, metal buildings consistently outperform other construction methods for most commercial projects.

Builder Lessons Learned: What Real Buyers Wish They Knew Sooner

Even with the advantages of pre-engineered metal buildings, many first-time buyers face unexpected costs: not because the system is flawed, but because some details get overlooked during early planning.

Based on real builder forums and buyer experiences, here are some hard-earned lessons and smart tips that can help you avoid budget surprises:

What Smart Builders Do Differently

- Get at least 3 quotes and make sure they cover kit-only, installed shell, and turnkey options so you can compare apples to apples.

- Ask detailed questions: Especially about what’s not included (e.g., foundation, slab, site work, utilities).

- Plan your interior early: Fit-outs like HVAC, plumbing, and office finishes can easily double the base building cost

- Lock in your design before quoting: Even small layout changes mid-process can require structural recalculations and drive up costs

- Check quote validity: Most pricing is only good for 30–45 days in today’s market

While on a call with us, a potential customer shared that before reaching out, they assumed their steel building would cost around $220K based on an initial quote they had. As we talked through the full scope: site prep, slab, doors, and utilities, they realized the true total would be much closer to $320K.

How We Help Clients Avoid These Pitfalls

This is exactly why we focus on transparent quoting, detailed scoping, and educating our clients early in the planning phase. Our goal is to make sure you’re not just buying a building, you’re building a solution that works long-term, with no surprises.

Whether you’re comparing kit-only pricing or planning a turnkey commercial facility, we help you price it right from day one. Request a quote today.

When to Lock in Your Metal Building Price?

In today’s market, waiting to “time” the perfect moment rarely works in your favor. Even if steel prices soften slightly, labor, concrete, and freight costs continue to trend upward, and delays can quickly erase any short-term savings.

The best time to lock in pricing is when your project is ready to move forward, not just when prices look favorable.

Lock in your quote when:

- Your site is ready or grading is scheduled

- You’ve secured financing or capital approval

- Your design and permitting scope is clear

Most suppliers in 2026 offer 30–45 day quote holds, but after that, prices may be subject to change due to material or freight fluctuations.

Pro Tip: Locking your quote at the right time gives you price protection and ensures your project stays on schedule without last-minute surprises.

With the right planning, you can lock in pricing confidently and move forward without unnecessary delays or budget creep.

2026 Metal Building Cost Planning Checklist

Before requesting quotes, it’s essential to plan your project with as much clarity as possible. This helps you get accurate pricing, avoid missed line items, and reduce costly surprises later in the process. Use this checklist to make sure you’re ready:

Pre-RFQ Planning Checklist

- Finalize building size, shape, and interior layout

- Determine insulation type and energy code requirements for your region

- Get at least 3 quotes: kit-only, installed shell, and full turnkey

- Factor in slab, site grading, permits, and utility connections

- Include architectural upgrades (doors, windows, façade features) if needed

- Ask suppliers about certifications like MBMA and IAS

- Confirm how long each quote is valid (typically 30–45 days)

- Plan a 15–25% contingency buffer for unexpected costs or upgrades

Pro Tip: The more detailed your inputs, the more accurate and reliable your quotes will be.

Download Your 2026 PEMB Budget Planning Checklist (PDF) to simplify your planning and keep everything organized.

Ready to Get Your Custom Quote? Compare pricing for kit-only, installed shell, or turnkey builds

FAQ: Commercial Metal Building Costs in 2026

Q1. Are metal buildings the most cost-effective option for commercial construction in 2026?

Yes. Pre-engineered metal buildings (PEMBs) are still the most cost-effective option for many commercial uses. On average, they cost 30–50% less than concrete and 20–40% less than wood framing, while offering faster build times and easier future expansion.

Q2. How long does it take to build a 10,000 sq ft metal building?

A typical 10,000 sq ft turnkey PEMB takes about 16 to 24 weeks to complete. This includes permitting, grading, slab work, steel erection, and basic interior finish.

Q3. Do metal building kits include the foundation?

No. Most PEMB kits include the building structure only. The foundation, slab, and site work are separate and usually add $6–$10 per square foot depending on soil, frost line, and grading needs.

Q4. Can I save money by managing the build myself?

Possibly, but it comes with risk. If you have reliable subcontractors and know local building codes, you might save on general contracting fees. But many self-managed builds experience delays, coordination issues, and surprise costs.

Q5. Should I wait to buy in case steel prices drop?

Unlikely. Even if steel prices dip slightly, rising labor, concrete, and freight costs in 2026 usually offset any material savings. Waiting often leads to higher total costs, not lower.

Q6. What’s the biggest hidden cost in a metal building project?

Site preparation and foundation work. Many buyers underestimate costs for grading, excavation, and concrete. In some cases, these can add 25–40% to the total project budget.

Q7. How much does a turnkey metal building really cost in 2026?

In 2026, a fully installed commercial metal building typically costs $28 to $50+ per square foot, depending on design complexity, location, and interior build-out requirements.

Q8. Are metal buildings suitable for cold or high-snow regions?

Yes, but they require proper engineering. Buildings in snow or wind-prone zones need additional structural reinforcement and insulation. Always ensure your design meets local load requirements and energy codes.