Cold-formed steel buildings, also called light-gauge steel buildings, are a popular choice for small to mid-sized commercial and industrial projects across the U.S. Lightweight, cost-effective, and quick to assemble, they offer a flexible alternative to heavier structural systems.

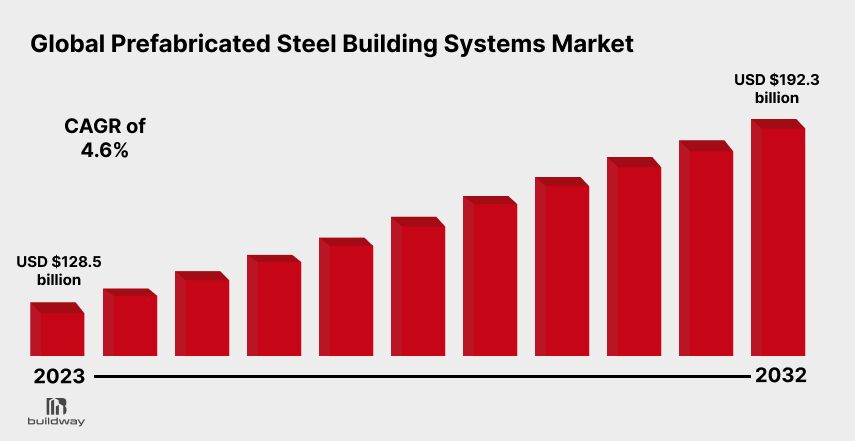

Reflecting this demand, the global cold-formed steel market hit $128.5 billion in 2023 and is projected to reach $192.3 billion by 2032, growing steadily at 4.6% annually.

But, with so many steel building types to choose from: rigid frame, Quonset and hybrid. It’s easy to get overwhelmed. This blog explains what cold-formed steel buildings are, how they’re built, what they cost, and how they compare to other options.

What Is a Cold-Formed Steel Building?

Cold-formed steel buildings use thin, high-strength steel sheets that are bent into shape without using heat. These components are known as “cold-formed” or “light-gauge” because they’re formed at room temperature through a process called roll forming.

The resulting framing members: C-shaped or Z-shaped studs, joists, and channels, are precise, lightweight, and highly consistent. This makes them ideal for pre-engineered structures like:

- Office buildings

- Light industrial units

- Retail spaces

- Self-storage facilities

Unlike hot-rolled steel (used in rigid frame buildings), cold-formed components don’t require welding or heavy equipment on site. Instead, they’re assembled with screws and fasteners, making them ideal for projects that prioritize speed and flexibility.

Cold-Formed vs Hot-Rolled Steel

| Feature | Cold-Formed Steel | Hot-Rolled Steel |

| Manufacturing | Room-temperature roll forming | High-heat rolling mill |

| Material Thickness | Thin (16–26 gauge) | Thick (I-beams, wide flange) |

| Assembly | Screws, no welding | Welding, bolts |

| Best For | Small-to-midsize commercial | Large clear-span structures |

Cold-formed steel is more efficient for smaller projects, while hot-rolled (rigid frame) is better suited for buildings requiring long, clear spans or heavy equipment loads.

How Cold-Formed Steel Buildings Are Designed & Built

Cold-formed steel buildings are fully engineered to meet your project’s specific requirements, then manufactured, packaged, and shipped as a ready-to-assemble kit. This streamlined process allows for faster construction timelines, lower labor costs, and fewer surprises on site.

Here’s what the typical build process looks like:

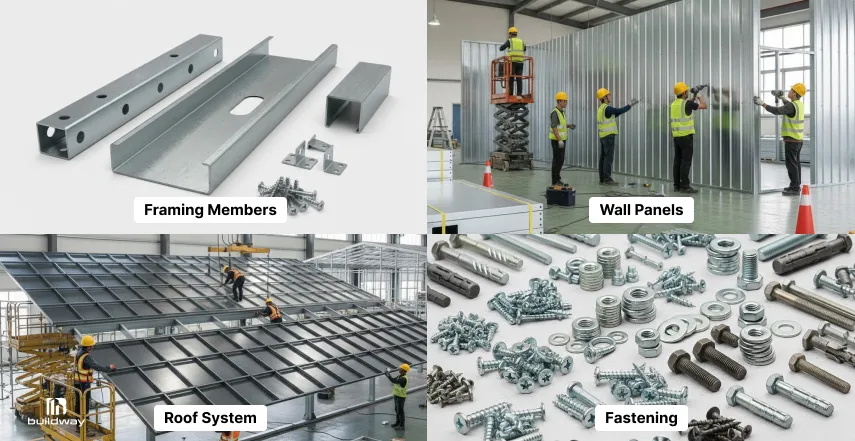

- Framing Members: Includes C-studs, joists, trusses, and girts, which form the building’s structural frame and support walls, floors, and the roof.

- Wall Panels: Usually corrugated steel sheets, though other cladding options like insulated panels or siding may be used.

- Roof System: Typically a lightweight, pitched metal roof, designed to handle rain, snow, and wind efficiently.

- Fastening: All components are connected with self-tapping screws, making assembly quicker and safer. No welding required.

Typical Framing Components

Cold-formed steel buildings rely on a system of lightweight yet strong framing elements that work together to support the structure. Each component has a specific role in carrying loads and connecting the walls, floors, and roof into one unified frame. Here’s a quick breakdown of the key components and what they do:

- Studs: Vertical members that form the walls and support vertical loads.

- Joists: Horizontal supports used for floors and ceilings.

- Trusses: Triangular roof structures that span wider distances without needing interior columns.

- Girts: Horizontal framing members attached to wall columns to support wall panels.

- Purlins: Horizontal members placed across roof trusses to support the roofing panels.

These parts fit together with precision, allowing for a fast and accurate assembly.

Engineering & Code Requirements

Cold-formed steel buildings must be properly engineered to meet local building codes and safety standards. These requirements ensure the structure can handle environmental forces and perform reliably over its lifespan. Key engineering considerations include:

- Wind Loads: Designed to withstand region-specific wind speeds and pressure requirements.

- Snow Loads: Engineered to support snow accumulation, especially in northern and mountain states.

- Seismic Conditions: Additional reinforcement for earthquake-prone areas such as California and the West Coast.

- Code Compliance: Must meet International Building Code (IBC) requirements and AISI S100 standards for cold-formed steel design.

Proper engineering is critical, especially since cold-formed members can buckle without the right bracing and load calculations.

Cold-Formed Steel Building Spans & Size Limits

Most cold-formed steel buildings are limited to clear spans of 50–70 feet, though this varies by design and load requirements. Widths beyond that may require hybrid solutions or upgraded framing.

| Span Width | Typical Use |

| 20–40 ft | Small offices, retail, storage |

| 40–60 ft | Warehouses, flex spaces |

| 60–70+ ft | May require hybrid systems |

When a larger, open interior is needed such as for manufacturing or hangars: a rigid frame (I-beam) structure is usually better suited.

Understanding the Size Limits of Cold-Formed Steel Buildings

While cold-formed steel offers flexibility in layout and design, it does come with some physical limitations, especially for large-scale or high-clearance projects. Here’s what to keep in mind:

- Width: Typically maxes out around 40 feet for clear-span designs. Wider buildings need interior columns or hybrid systems.

- Height: Practical wall heights usually top out around 20–26 feet, depending on wind and load factors.

- Length: More flexible. Buildings can often be extended in modular bays (e.g. 10′ or 12′ increments).

- Roof Pitch: Cold-formed systems usually use lighter pitched roofs; complex roof designs may require custom engineering.

- Load Limits: Heavier loads (roof-mounted equipment, snow, cranes) can stress cold-formed members unless reinforced.

These limits don’t make cold-formed steel inferior. It simply means it’s best suited for small to mid-size buildings with moderate span and height requirements.

Cold-Formed Steel Building Costs

Cold-formed steel buildings are widely known for their cost-efficiency, making them a smart choice for many commercial and light industrial projects. Their lightweight materials and simplified construction help reduce both material and labor costs. Below, we break down typical price ranges and the key factors that influence overall cost.

Average Cost Range:

- $10–$25 per sq. ft. for shell-only kits (structure, roof, wall panels)

- $25–$60+ per sq. ft. for fully built-out spaces with insulation, interiors, MEP systems

What Impacts Price?

While cold-formed steel buildings are generally affordable, total project cost can vary significantly based on several key factors. Understanding these variables helps set realistic expectations early in the planning process.

- Size & Span: Wider spans and larger footprints require additional framing and engineering, increasing overall cost.

- Location: Labor rates, permitting, and engineering requirements vary by region and state.

- Wind, Snow & Seismic Loads: Higher environmental load requirements mean more bracing and heavier-gauge steel.

- Customization: Non-standard layouts, upgraded finishes, and architectural features add complexity and cost.

- Use Case: Simple storage buildings cost less than fully conditioned spaces with insulation, HVAC, and interior build-outs.

The more complex your building’s design, location, and performance requirements, the more you can expect to pay, so it’s important to align your building system with your specific project goals.

Cost vs Rigid Frame Buildings

Rigid frame (I-beam) buildings are stronger and better for clear spans over 80 feet, but they’re more expensive to engineer, fabricate, and erect.

- Cold-formed steel: lower cost for smaller projects, simpler labor

- Rigid frame: higher up-front cost, but needed for large or heavy-duty buildings

Cost vs Quonset Buildings

Quonset huts are often cheaper than cold-formed steel buildings, but far more limited.

| Feature | Quonset | Cold-Formed |

| Shape | Arched | Rectangular |

| Expandability | Difficult | Easy to add-on |

| Interior Layout | Limited | Flexible |

| Best For | Equipment storage | Offices, retail, flex |

Still not sure which steel building type fits your project? Compare All Steel Building Types or give us a call directly and we will help you build a plan for your next project.

Best Uses for Cold-Formed Steel Buildings

Cold-formed steel buildings are best suited for low-rise projects where fast construction, affordability, and interior flexibility take priority over large clear spans or heavy load requirements. They’re a great fit for owners and developers who need quick turnaround times and scalable designs, especially in commercial and light industrial sectors. Here are some of the most common and effective applications:

- Retail and Storefronts: Ideal for strip malls, showrooms, and standalone shops that need open floor space and quick buildouts.

- Office Buildings: Great for small-to-midsize office layouts, especially in business parks or mixed-use developments.

- Self-Storage Facilities: A cost-effective way to build single- or multi-story storage units with repeatable designs.

- Light Industrial & Assembly Shops: Suitable for facilities that don’t require heavy machinery or cranes but need open bays and functional layouts.

- Building Additions: Perfect for expanding existing commercial or industrial buildings due to lightweight construction and ease of integration.

- Maintenance Shops & Utility Buildings: Efficient for garages, workshops, and service bays with moderate space and equipment needs.

These use cases take full advantage of what cold-formed steel systems do best: delivering dependable performance at a lower cost and faster pace.

Limitations & Drawbacks to Know Before Buying

Cold-formed steel buildings offer speed, affordability, and versatility—but they’re not ideal for every type of project. Understanding the system’s limitations upfront can help you avoid costly missteps and ensure you choose the right structural solution for your needs.

Limitations to Consider:

- Clear Span Limits: Typically max out around 40 feet; wider spans require interior supports or a switch to rigid frame systems.

- Not Suitable for Heavy Equipment: These buildings aren’t designed for crane loads or industrial-scale machinery.

- Labor-Intensive Assembly: Screwed connections (vs welded) mean longer installation times, especially on larger builds.

- More Flex Under Load: Cold-formed steel can experience greater deflection than rigid frame systems under heavy loading.

- Misuse Risks: Problems arise when cold-formed systems are used beyond their structural limits, often due to improper planning or cost-cutting.

Not recommended for: Hangars, large clear-span warehouses, or heavy manufacturing facilities that demand high-load performance or wide open interiors.

Being realistic about these limitations is key to making a confident, well-informed decision.

Cold-Formed Steel vs Other Steel Building Types

Not all steel buildings are created equal. Cold-formed steel systems are best suited for smaller, budget-conscious projects, while rigid frame and Quonset buildings each have their own strengths and limitations.

Use the table below to get a quick side-by-side comparison of the three most common steel building types:

| Feature | Cold-Formed | Rigid Frame | Quonset |

| Cost | Lowest | Highest | Low |

| Span Capacity | Limited | Very High | Limited |

| Interior Flexibility | High | High | Low |

| Expansion | Easy | Easy | Hard |

| Aesthetics | Customizable | Customizable | Limited |

In short, Cold-formed steel is great for small, flexible builds. Rigid frames suit large, open spaces, while Quonsets are best for simple, low-cost storage.

Not sure which building system fits your needs best? Explore our full steel building comparison guide.

Cold-Formed vs Rigid Frame Steel Buildings

Cold-formed is easier and cheaper to build for small-to-medium projects. A rigid frame is stronger, better for long spans, and ideal for industrial uses.

Use cold-formed if:

- You’re building under 40 ft wide

- You want a clean office or retail look

- You’re cost-conscious and don’t need heavy load support

Cold-Formed vs Quonset Buildings

Quonsets are great for budget equipment storage but lack flexibility and aesthetics.

Choose cold-formed over Quonset when:

- You need interior wall layouts

- You want future expansion

- Appearance and customization matter

To sum it all up, Cold-formed steel offers a balanced middle ground: more versatile than Quonset buildings and more affordable than rigid frame systems for smaller-scale projects.

Is a Cold-Formed Steel Building Right for Your Project?

Cold-formed steel buildings are a smart, efficient choice for many commercial and light industrial applications, but they aren’t one-size-fits-all. If your project meets the following criteria, cold-formed steel could be a perfect fit:

- Building width under 40 feet

- No heavy equipment, cranes, or high-load requirements

- Commercial, office, storage, or light industrial use

- Budget-conscious timeline and construction goals

- Need for fast, flexible, and customizable design

However, you may want to consider other options if:

- Your project requires large clear spans or column-free interiors

- You’re designing a high-load, multistory, or heavy-use industrial facility

Still weighing your options? We are here to help. Give us a call or choose a building directly from our clearance sale without any hassle and at a very affordable price.

Frequently Asked Questions (FAQ)

1. How much does a cold-formed steel building cost per square foot?

A basic cold-formed steel building shell typically costs $10–$25 per square foot. When fully finished with insulation, HVAC, and interiors, total costs can range from $25–$60+ per square foot, depending on complexity, location, and use.

2. What is the maximum span for cold-formed steel buildings?

Cold-formed buildings generally support clear spans up to 60–70 feet. Projects requiring wider spans often need a hybrid system or a rigid frame (I-beam) structure for added strength and stability.

3. Are cold-formed steel buildings durable in harsh weather?

Yes. When properly engineered, cold-formed steel buildings are designed to meet wind, snow, and seismic requirements according to the International Building Code (IBC) and AISI S100 standards.

4. When should I avoid using a cold-formed steel building?

Avoid cold-formed systems for projects that need:

- Clear spans over 40 feet

- Heavy equipment loads or cranes

- High-load industrial use or multi-story structures

In such cases, a rigid frame system is usually more appropriate.

5. How does a cold-formed steel building compare to rigid frame and Quonset buildings?

Cold-formed buildings are more affordable and flexible than rigid frame systems and offer better customization than Quonset huts. However, they can’t match the load capacity or span strength of rigid frame buildings.

6. Are cold-formed steel buildings easy to expand later?

Yes. Cold-formed steel structures are often designed with modular bays, making future expansion relatively simple and cost-effective. This makes them ideal for growing businesses.

7. Do cold-formed steel buildings require welding on site?

No. Cold-formed systems are typically bolt-together or screw-fastened, eliminating the need for welding and reducing labor costs and on-site safety risks.