If you’re exploring steel building quotes and keep running into terms like Cold-Formed vs I-Beam vs Quonset, you might be wondering: “Aren’t these all just steel buildings?” It’s a fair question after all, they’re all made of steel, they all get delivered as pre-engineered kits, and they all promise durability.

But, not all steel buildings are built the same. In fact, the structural system behind your building plays a major role in how your project performs, how it looks, and how much it costs: both upfront and long-term. That’s why comparing Cold-Formed vs I-Beam or even I-Beam vs Quonset matters more than people think. The type of steel frame you choose will directly impact:

- Total project cost (materials, install, labor)

- Clear-span width and layout flexibility

- Ease of installation: DIY or pro crew?

- Suitability for different uses like shops, storage, homes, or warehouses

- Engineering strength including snow, wind, seismic, and load requirements

- Lead times and speed to build

And this is where things can get a little confusing. Building quotes often focus on size and price, but don’t always spell out exactly what type of frame system is included. Understanding the difference between cold-formed, I-beam, and Quonset structures can help you make sure you’re choosing the right fit for your project.

In this blog we’ll walk you through the pros and cons of each in plain English and compare them by cost, span, load, installation needs, and typical applications. We’ll also bust a few common myths (especially around cold-formed steel) and help you figure out which type makes the most sense for your project, budget, and timeline.

Cold-Formed vs I-Beam vs Quonset: Quick Comparison at a Glance

Before understand the Cold-Formed vs I-Beam vs Quonset differences, here’s a side-by-side comparison of the key differences between cold-formed steel, I-beam (rigid frame), and Quonset huts. This table gives you a fast, high-level overview of how they stack up in terms of cost, span capacity, ease of installation, and typical use cases, so you can quickly see which option might be the best fit for your needs.

| Feature | Cold-Formed Steel | I-Beam (Rigid Frame) | Quonset Hut |

|---|---|---|---|

| Installed Cost | $9–$16 per sq ft | $12–$22+ per sq ft | $8–$14 per sq ft |

| Clear Span Width | 20–60 ft (typical) | 30–300+ ft | 20–100 ft |

| Interior Layout | Open, some bracing | Fully open, no bracing | Open, curved walls limit use |

| Engineering Strength | Moderate to high (engineered) | Very high (industrial-grade) | Moderate (based on arch) |

| Lead Times | 3–6 weeks | 8–12+ weeks | 3–6 weeks |

| Install Difficulty | Moderate DIY to Pro Crew | Requires crane & pro crew | Highly DIY-friendly |

| Best For | Shops, barndos, garages | Warehouses, commercial, ag | Storage, barns, workshops |

As you can see, each frame type brings its own strengths depending on your priorities, whether that’s budget, span, DIY potential, or long-term durability. This quick comparison gives you a solid starting point to understand your options. In the next sections, we’ll break down how each building system is constructed, how it performs under load, and where it makes the most sense to use.

Cold-Formed vs I-Beam vs Quonset: What These Steel Building Types Actually Are?

Before you decide which steel building system is best for your project, it’s important to understand how each structure is built including the materials used, how the framing is shaped, and how the building is assembled on-site. These core differences are what affect your building’s performance, cost, installation method, and suitability for different uses. Let’s take a closer look at how cold-formed, I-beam (rigid frame), and Quonset buildings are designed and constructed.

1. Cold-Formed Steel Buildings: Lightweight, Efficient, and Code-Compliant

Cold-formed steel buildings are a popular choice for smaller to mid-sized structures such as shops, garages, and barndominiums. They’re made from light-gauge steel that’s shaped at room temperature (cold-formed) and then bolted together on-site. Despite being lightweight, these structures are fully engineered to meet local building codes making them a strong, budget-friendly option when designed correctly.

Here’s what sets them apart:

- Constructed from galvanized C-channel and Z-purlin members

- Steel sections are roll-formed from coils without heat

- Lightweight components are easy to handle and assemble

- Delivered as a pre-engineered kit. It includes framing, wall/roof panels, fasteners, and hardware

- Requires bracing systems (like knee braces or X-bracing) to handle lateral loads

- Commonly used for shops, garages, storage buildings, and smaller barndos

- More DIY-friendly than heavier systems, though a crew is still recommended for larger spans

Good to Know: When engineered properly, cold-formed steel buildings meet the same IBC codes as red iron structures: they’re not “temporary” or “low-grade,” as some misconceptions suggest.

2. I-Beam (Rigid Frame) Steel Buildings: Built for Strength, Spans, and Heavy Loads

I-beam, or rigid-frame, buildings are the workhorses of the steel construction world. They use hot-rolled or welded steel beams (also called “red iron”) to create extremely strong structural frames. These buildings are ideal for large clear spans, tall sidewalls, and heavy-duty use including industrial, agricultural, and commercial projects.

Key characteristics of I-beam steel structures:

- Built from hot-rolled H-beams or welded wide-flange columns and rafters

- Steel components are pre-fabricated in a factory, then shipped to your site

- Assembled using bolt-up connections. It requires lifts or cranes due to beam weight

- Can span over 300 feet without interior columns

- Excellent for buildings that require: Overhead cranes, Second floors or mezzanines, Tall equipment bays

- Common in warehouses, factories, airplane hangars, commercial buildings, and large ag barns

- Supports longer bay spacing, fewer columns, and better load distribution

Quick Tip: When someone refers to a “red iron building,” they’re usually talking about an I-beam system. These buildings are often designed for higher loads, custom spans, and demanding structural needs.

3. Quonset Hut Steel Buildings: Simple, Self-Supporting Arches for Storage and Agricultural Use

Quonset buildings stand out thanks to their distinctive arch shape and all-in-one construction method. They’re made from corrugated, curved steel panels that bolt together to form a self-supporting shell. While Quonsets technically use cold-formed steel, their structural behavior and use-cases are different enough to treat them as a separate category.

What makes Quonsets unique:

- Constructed from corrugated galvanized steel panels curved into an arch

- The panels form both the roof and walls. No need for a separate frame

- Designed for quick assembly, often by DIY builders with basic tools

- Typically installed on a simple slab foundation, bolted around the perimeter

- Very cost-effective for basic storage or agricultural buildings

- Span widths usually range from 20 to 100 feet depending on the model

- Common for hay barns, equipment sheds, vehicle storage, or workshops

- Fewer interior finish options due to curved walls (limits insulation, drywall, shelves, etc.)

Good to Know: Quonsets are highly durable and rust-resistant when properly sealed. However, their shape can limit usable wall height and large front-end openings, something to consider if you plan on installing tall roll-up doors or large machinery.

Structural Comparison: Spans, Loads & Strength

When comparing Cold-Formed vs I-Beam systems, or looking at I-Beam vs Quonset structures, the frame type you choose directly affects how wide your building can be, how open the interior is, and how well it handles things like snow, wind, and roof loads. Some systems are better suited for small shops or garages, while others are built for long clear spans or heavy-duty use like cranes or second floors. Let’s take a look at how cold-formed, I-beam, and Quonset buildings compare in terms of strength and span performance:

1. Cold-Formed: Versatile for Small-to-Mid Buildings

- Spans up to ~60 ft are common for full cold-formed

- Wider buildings may use hybrid frames (cold-formed + red iron beams)

- Engineering is critical: spacing, bracing, and purlins affect load performance

Cold-formed systems handle typical snow/wind loads and are common in:

- Shops

- Garages

- Barndominiums

- Equipment storage buildings

2. I-Beam: Best for Heavy-Duty Requirements

- Can clear-span 300+ feet

- Built for snow zones, wind zones, and equipment loads

- Ideal for buildings that need:

- Overhead cranes

- Mezzanines or second floors

- Tall sidewalls (18+ feet)

- Long bays or wide-open interiors

3. Quonset: Self-Supporting but with Limitations

- Span depends on arch model, typically up to 100 ft

- No need for trusses or rafters. Panels support the entire load

- Limited door width on curved front ends (workarounds exist)

- Sidewall height is lower near the base. It may limit interior use

As you can see, each frame type has its own strengths when it comes to spans and structural loads. Choosing the right system depends on your building size, load requirements, and how you plan to use the interior space. Up next, we’ll break down how these choices impact your budget, installation time, and long-term durability.

Cost Comparison: What Will Each System Cost You?

The cost gaps in Cold-Formed vs I-Beam vs Quonset buildings are bigger than most people realize, but it’s important to look beyond the sticker price. The total cost of your building depends not only on materials, but also on installation, delivery, foundation requirements, and the size and complexity of your design. In this section, we’ll break down installed price per square foot, span capabilities, and the factors that affect lead times, shipping, and on-site assembly for each frame type.

Installed Price Per Square Foot

Here’s a general look at average installed prices for Cold-Formed vs I-Beam vs Quonset buildings. These prices reflect both the building kit and labor to erect it, but do not include interior finishes, concrete work, or utilities.

| System | Price Range (Installed) | Notes |

|---|---|---|

| Cold-Formed | $9–$16 / sq ft | Efficient for small/medium builds |

| I-Beam | $12–$22+ / sq ft | Price rises with custom spans/heights |

| Quonset | $8–$14 / sq ft | Most budget-friendly upfront |

Keep in mind: These are estimates and can vary based on your location, code requirements, snow/wind loads, building size, and chosen accessories (doors, insulation, etc.).

These prices include materials + erection (labor), but not:

- Interior finishing

- Electrical, plumbing, or HVAC

- Site work and foundation (varies by location)

Span Capabilities Summary

One of the biggest differences between these systems is how wide they can go without interior support columns, also known as clear span. The wider the span, the more flexibility you’ll have with your interior layout, especially for equipment storage, open shops, or finished living areas.

| Frame Type | Typical Width Range | Ideal For |

|---|---|---|

| Cold-Formed | 20–60 ft (some up to 100) | Shops, garages, light commercial |

| I-Beam | 30–300+ ft | Warehouses, arenas, large ag storage |

| Quonset | 20–100 ft | Dry storage, ag barns, workshops |

Pro Tip: Cold-formed buildings over 60 ft often require hybrid framing (with structural steel elements) to maintain structural integrity. I-beam is your best option for very wide, clear-span interiors with no obstructions.

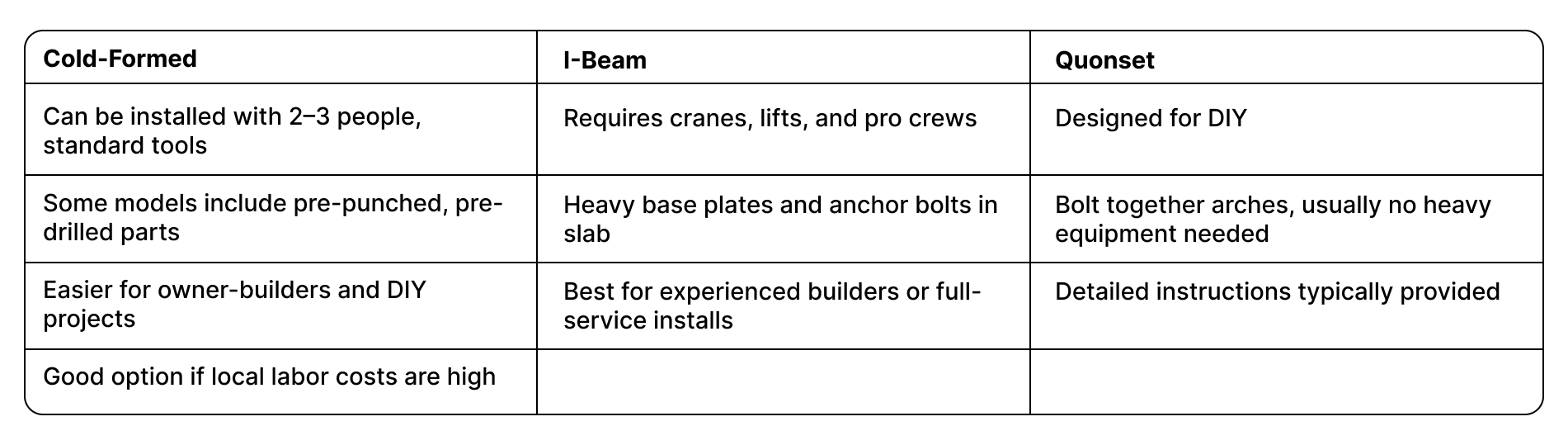

Lead Times, Shipping & Assembly

Steel building systems also differ in how quickly they can be produced and delivered and in what kind of crew, tools, and equipment are required to assemble them on-site. Here’s how they compare:

| Factor | Cold-Formed | I-Beam (Red Iron) | Quonset |

|---|---|---|---|

| Lead Time | 3–6 weeks | 8–12+ weeks (custom-engineered) | 3–6 weeks |

| Shipping | Lighter loads, lower cost | Heavy loads, flatbeds | Palletized arch panels |

| On-Site Assembly | Bolt-together system | Heavy frames, cranes needed | Bolt panels together on slab |

Key Considerations:

- Cold-Formed: Faster to produce and ship, with lower weight = lower shipping cost. Can often be installed by a small crew with basic tools, depending on size and complexity.

- I-Beam: Typically takes longer due to the engineering and fabrication of custom frames. Requires cranes and professional erection crews due to the size and weight of steel members.

- Quonset: Designed for simplicity. Many kits are installed by owners themselves using common tools. Great for remote or rural properties with limited access to large equipment.

Before any Cold-Formed, I-Beam, or Quonset building arrives, make sure your foundation, access roads, and utilities are ready. Our guide on Metal Building Site Preparation: Everything to Do Before Your Kit Arrives walks you through every step.

Installation Requirements

While Quonset huts offer the lowest upfront cost, they come with layout limitations. Cold-formed buildings strike a balance between affordability, ease of installation, and customization, especially for smaller projects.

I-beam systems, while more expensive, are unmatched in strength, scalability, and design flexibility making them the go-to choice for larger, more complex structures. As always, the right choice depends on your project goals, budget, and timeline, not just price per square foot.

Want to see how these systems perform in real-world projects? Check out our completed builds on the Buildway Projects Page to see how different frame types are used across shops, barns, barndominiums, warehouses, and more.

Durability, Coatings & Longevity

When choosing a steel building, it’s not just the frame strength that matters, it’s how well the structure holds up over time. Factors like coating type, climate exposure, and maintenance needs play a big role in the long-term performance of your building. In this section, we’ll compare how each frame type protects against corrosion, what kind of maintenance you might need, and how each option stacks up when it comes to code compliance and lender acceptance.

Galvanized vs. Painted Steel: How Coatings Impact Longevity

The type of coating on your steel frame directly impacts its resistance to rust, especially in humid, coastal, or high-moisture environments.

| Frame Type | Coating Type | Rust Protection |

|---|---|---|

| Cold-Formed | Galvanized (zinc-coated) | Excellent. Built-in corrosion protection for moist climates |

| I-Beam | Red oxide primer paint | Good, but requires maintenance and potential re-coating |

| Quonset | Galvanized corrugated panels | High. Low-maintenance and long-lasting |

What’s the Difference?

- Galvanized steel is coated with a layer of zinc that acts as a barrier against rust. It’s applied during the roll-forming process and offers long-term protection, especially in areas with high humidity or salt in the air.

- Red iron (I-beam) components are typically coated with red oxide primer, which protects the steel during shipping and installation. However, over time, these painted surfaces may need to be touched up or repainted, particularly if scratched, exposed to standing water, or installed in coastal zones.

Pro Tip: If you’re building near the coast, in humid zones, or areas prone to condensation, galvanized steel is often the safer long-term bet unless you invest in additional coatings or sealants for red iron structures.

If you’re planning for better energy efficiency or moisture control especially in humid or cold climates, check out our guide on How to Insulate a Metal Building for Maximum Energy Efficiency.

Code Compliance & Lender Approval

Regardless of which steel frame system you choose: cold-formed, I-beam, or Quonset, your building must be engineered to meet local building codes. This includes requirements for snow loads, wind loads, seismic forces, and foundation design based on your exact location.

At Buildway, we provide stamped engineering drawings tailored to your site’s conditions, including:

- Wind and snow load ratings

- Seismic activity zones

- Soil-bearing capacity for foundations

- Local permit requirements

These documents are critical not just for construction, but also for securing financing and insurance.

What Lenders Typically Require:

To approve financing or loans for steel buildings, most banks and credit unions ask for:

- Stamped engineered plans

- Foundation design details

- Code compliance documentation

- Insurance-ready structural specs

Buyer Tips: How to Understand a Steel Building Quote

Getting a quote for a steel building can sometimes feel overwhelming, especially if you’re comparing offers from multiple companies. While most suppliers aim to provide a solid, code-compliant product, it’s still important to understand what’s included (and what’s not), so you can make the right choice for your needs, location, and budget. At Buildway, we believe in helping customers make informed, confident decisions. Here’s a quick guide to understanding what details to look for when reviewing a steel building quote:

Signs of a Detailed, Engineered Quote

A good steel building quote will typically include:

- Stamped engineering drawings: These confirm the building is designed to meet your local building codes, including wind and snow loads.

- Steel gauge thickness: Look for specs like 12–14 gauge for framing and 26 gauge for roof/wall panels. Lower gauge = thicker, stronger steel.

- Purlin and frame spacing: This affects structural strength and load distribution. Proper spacing ensures durability and stability.

- Clear span and load capacity ratings: Especially important in snow-prone, windy, or seismic zones and for buildings with equipment, second floors, or mezzanines.

- Foundation recommendations: Some suppliers include basic slab or pier guidance, while others provide full foundation drawings.

Details Worth Asking About

Sometimes, key specs are left out of a quote, not intentionally, but because every building is different. If something isn’t clear, it’s always okay to ask. Questions to consider:

- Are engineering plans included or optional?

- What wind/snow loads is the building rated for?

- What frame type is included (cold-formed, I-beam, Quonset)?

- Are doors, insulation, or foundation included or separate?

Understanding these factors will help ensure you’re comparing quotes accurately, not just on price, but on value, performance, and fit.

Need a quick way to compare quotes side-by-side? Download the Steel Building Quote Comparison Checklist. Use it to:

- Spot missing details before they become a problem

- Compare frame types, coatings, and engineering

- Ask the right questions for your site, loads, and timeline

- Make sure your building meets local code and permit requirements

Conclusion

No two building projects are the same and not every steel building quote will look identical. What matters most is that you choose a building system that’s engineered, transparent, and right for your specific goals.

Cold-Formed vs I-Beam vs Quonset: Final Verdict

| If You Need… | Choose… |

|---|---|

| Budget shop or garage | Cold-Formed or Quonset |

| Wide open spans (80+ ft) | I-Beam |

| Finished living space under 60 ft wide | Cold-Formed |

| Second story, tall interiors | I-Beam |

| Maximum DIY ease | Quonset |

| Fastest delivery | Cold-Formed |

| Cranes or overhead doors >16 ft wide | I-Beam |

| Dry ag storage (hay, grain, machinery) | Quonset or I-Beam |

At Buildway, we’re happy to walk you through your quote, explain your options, and make sure your project stays on track from day one.

So if you’re still weighing Cold-Formed vs I-Beam options, or trying to decide where I-Beam vs Quonset makes the most sense? Click here to request a custom recommendation. We’ll help you pick the right system based on your:

- Width and length

- Roof loads

- Doors and use case

- Location and timeline

Also check out the Top 7 Biggest Metal Building Kit Buying Mistakes to Avoid so you don’t walk into the same pitfalls that cost other buyers thousands.

FAQ’s

1. Are Quonset huts cheaper than I-beam buildings?

Yes, Quonset huts are generally cheaper than I-beam buildings. Their simple design, lightweight materials, and DIY-friendly assembly make them one of the most affordable steel building options, especially for agricultural storage, workshops, or garages. However, I-beam buildings offer more flexibility in layout, larger clear spans, and are better suited for commercial or custom residential use.

2. Is cold-formed steel strong enough for a barndominium?

Yes, cold-formed steel is strong enough for a barndominium when properly engineered. These buildings can easily support residential loads, insulation, interior finishes, and even partial second stories. For spans under 60 feet, cold-formed systems are a cost-effective and structurally sound choice for barndominiums.

3. Do lenders and building departments accept cold-formed steel buildings?

Yes, cold-formed steel buildings are accepted by both lenders and building departments, as long as the building is engineered to local codes. At Buildway, all our cold-formed kits come with stamped engineering drawings and foundation plans tailored to your location, which helps streamline permitting and financing approval.

4. How long do cold-formed vs I-beam vs Quonset steel buildings last?

With proper coatings and maintenance, steel buildings can last 40 to 60 years or more. Galvanized cold-formed and Quonset systems offer strong resistance to rust and corrosion, especially in humid or coastal areas. I-beam buildings may require additional maintenance on painted surfaces over time, but are equally durable when cared for properly.